|

|

Newsletter December 2025 | Menu of

Newsletters

When measuring

qualities of interacting surfaces in relative motion, such as the

coefficient of friction, friction force, adhesion, wear volume, lubrication,

and deformation, the tribometer is the instrument of choice. Typically,

tribometers are used to characterize rigid substrates utilizing a rigid probe,

which measures friction forces through deflections of the cantilever

supporting the probe.

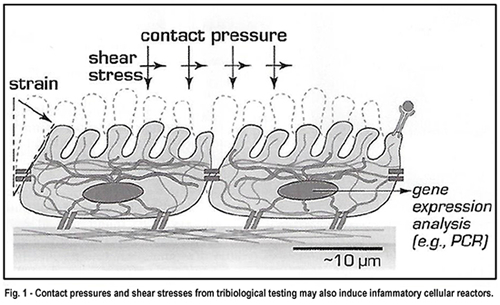

But characterizing soft surfaces such as cells or

other delicate tissues with tribometry presents a significant challenge. Hard

probes used to test such surfaces damage the cells and tissues. Contact

pressures and shear stresses from tribological testing may also induce

inflammatory cellular reactions.

"Soft implant materials increasingly

being used in biomedicine for contact lenses, clamps, catheters and soft

tissue prostheses present significant experimental challenges during

surface characterization with tribometry," says Prof. Angela Pitenis,

Interfacial Engineering Lab, University of California, Santa Barbara (UCSB).

"Over the last two years my lab has been investigating microscale contact areas

and forces between aqueous gels and cells. We want to understand how cells

respond to mechanical stimulation caused by soft implants."

"The need to

examine biocompatibility of these implant materials has introduced

opportunities to develop specialized instrumentation for tribological studies

of these low friction aqueous gels, cells and tissues," says Pitenis. "So we

developed our own custom instruments with the ability to observe and monitor

changes in the contact area within the deformations of these soft

materials."

"We design and fabricate precise in situ instrumentation

that interrogates microscopic contacts of cells under microscale forces (25 mN

to over 1,000 mN)," adds Pitenis. "A wide variety of cell and tissue types,

along with soft biocompatible materials are frequently used in combination to

create model interfaces from which to study fundamental mechanisms

associated with biological responses to contact and shear."

|

Vibration

Isolation: The lab's biotribology research is conducted on top of an

air-cushioned optical table with 10 N and 25 N stages to provide passive

damping. Because the lab's research often measures very low friction

coefficients of approximately 0.01 and below, any vibrations from the

environment could interrupt measurements.asdfasdf"We measure forces on the

order of micronewtons," says Pitenis. "Vibration isolation is critical to our

research. Footfall from someone walking by, the closing of doors — even

with the optical table, these vibrations will still be

measured."

Consequently, the lab has added another layer of vibration

isolation designed to more thoroughly cancel out low-frequency

horizontal-direction vibrations coming up through the floor.

"We

selected a negative-stiffness vibration isolator from Minus K Technology," says

Pitenis. "It supports the biotribometer and the specimen container. The

isolator is positioned on the breadboard. The negative-stiffness isolator is

working fantastically," she says. "It is an excellent design choice for our

research."

Full

article...

|

|

|

Previous

Newsletters

|

|

|

|