|

The Moulé Group, at the University of

California/Davis, has been embarked on a series of solution-based methods,

called Dopant Induced Solubility Control, that allow patterning of organic

semiconductors from solution with sub-micron resolution. Supporting this

nanoscale research, the Group utilizes Negative-Stiffness vibration isolation,

developed by Minus K Technology, to provide the needed stability for patterning

with atomic force microscopy.

|

|

Organic

semiconductors are non-metallic materials that exhibit semiconductor

properties, whose building blocks are polymers made up of carbon and hydrogen

atoms. Like all semiconductors, the conductivity of semiconducting polymers

changes by orders of magnitude when doped with electron donating or extracting

dopants.

Polymeric semiconductors combine many of the electrical

properties of inorganic semiconductors with the mechanical flexibility and

chemical processability of organic materials.

For instance, solution

processible polymeric semiconductors can be deposited from solution over large

areas or on curved surfaces, greatly reducing production costs compared to

conventional metallic semiconductors. Promising material properties have

motivated a rapid increase in demand for low-cost, high-throughput and

high-resolution fabrication techniques.

Patterning Organic

Semiconductors

Patterning organic semiconductors via traditional

solution-based microfabrication techniques, however, is precluded by undesired

interactions between processing solvents and the organic material. These

materials are generally mutually soluble with other organics, preventing

solution-based deposition of complex patterned structures.

"One of the

really hard problems in solution-processed organic devices is to develop

methods to pattern the organic semiconductor on the nanoscale," said Goktug

Gonel, a researcher with the Moulé Group, at University of California,

Davis. "The reason this problem is difficult, is that fluid dynamics and drying

dominate the deposition process, leaving typical patterns with at least tens of

micrometers in diameter, and uneven thickness."

The Moulé Group

specifically focuses on using structural and dynamic measurement techniques to

quantify the effects of solution processing and patterning on material

morphology and device architecture. The Group is working on a series of

solution-based methods called Dopant Induced Solubility Control that allows the

patterning of organic semiconductors from solution with sub-micron

resolution.

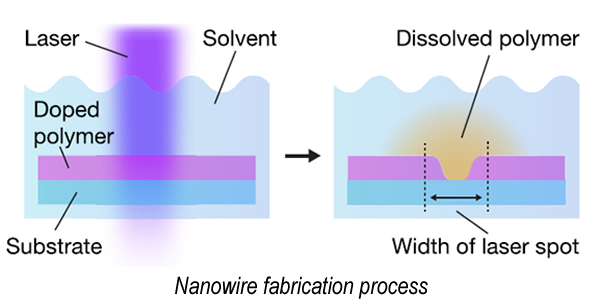

"Dopant Induced Solubility Control presents a relatively new

method for patterning conductive polymers utilizing a change in polymer

solubility," continued Gonel. "By sequentially doping and de-doping films,

polymer solubility can be switched on and off at will. Atomic force microscopy

(AFM) imaging shows that this process is capable of generating both positive

and negative features, with widths and edges sharper than obtainable

previously."

"In addition, by changing the solvent used during

patterning, the same process allows for optical de-doping," added Gonel. "Using

a novel hyperspectral infrared imaging method, photo-induced force microscopy

(PiFM), we find our method allows for optical control of doping level with

similar subdiffraction-limited resolution. Together, our results illustrate how

the ability of dopants to tune not only work function and carrier densities,

but also physical properties such as solubility, along with the wide range of

easily accessible chemistry in these materials, can drastically simplify

solution-based processing of complex structures."

Vibration

Isolation

During semiconductor device manufacturing, wafer testing is

performed, where all individual integrated circuits that are present on the

wafer are tested for functional defects by applying special test patterns. The

wafer testing is performed by a piece of test equipment called a wafer prober.

For electrical testing, a set of microscopic contacts or probes, called a probe

card, are held in place while the wafer, vacuum-mounted on a wafer chuck, is

moved into electrical contact.

The Located on the third floor of a

building on the UC Davis campus, the Moulé Group's nanometer-scale

research is affected by ambient vibrations.

Full article

with Minus K solution... |