|

|

Newsletter July 2025 | Menu of

Newsletters

Cilia, small,

slender, hair-like structures present on the surface of all mammalian cells,

play a major role in locomotion and are involved in mechanoreception. Ciliary

motion in the upper airway is the primary mechanism by which the body

transports foreign particulates out of the respiratory system to maintain

proper respiratory function.

Ciliary motion plays a critical role in the

overall respiratory health of the upper airway. Cilia beat at a native

frequency, and in a synchronized pattern, to continuously transport foreign

particulate trapped in a layer of mucous out of the upper airway. The ciliary

beating frequency (CBF) is often disrupted with the onset of disease as well as

other conditions, such as changes in temperature or in response to drug

administration. Disruption of ciliary motion can lead to severe respiratory

diseases and compromised respiratory function.

Measuring CBF is a

technical challenge and difficult to perform in vivo. Current imaging of cilia

motion relies on microscopy and high-speed cameras that cannot be easily

adapted to in vivo imaging.

Phase-contrast microscopy (PCM) is the

standard for measuring CBF but has limitations. PCM does not permit

appreciation of how CBF varies across the complex landscape of the nasal vault

and sinus tissues. Additionally, optical coherence tomography (OCT) has proven

to be a powerful imaging modality capable of visualization of ciliary activity,

but its field of view is limited.

Spectrally Encoded Interferometric

Microscopy

A team of scientists and engineers at the Chen F-OCT Group,

part of the Beckman Laser Institute of the department of biomedical engineering

at the University of California, Irvine (UCI), have designed a system capable

of overcoming these limitations. The groups current research focus is on

investigating light/tissue interactions; developing medical diagnostic and

therapeutic devices and instruments using advanced optical, microfabrication,

and biomedical technologies; and applications of these technologies for the

early diagnosis of disease.

Previously, the group developed a phase

resolved Doppler optical coherence tomography (PR-D-OCT) system that was able

to obtain lateral cross-sectional images of cilia and cilia movement in

real-time. The inventors realized the need to observe the surface dynamics of

cilia over time and spatially, so they developed a spectrally encoded

interferometric microscopy (SEIM) system with PR-D technology. As a result,

fast, high-resolution en face images of human CBF can be captured and processed

in real-time. Additionally, the integration of PR-D-OCT with PR-D-SEIM provides

a multidimensional view of cilia.

SEIM has emerged as a high-speed,

high-resolution methodology, allowing for visualization of both temporal and

spatial ciliary motion patterns across the surface of upper airway tissues, as

well as propagation of metachronal wave, says Zhikai Zhu, PhD candidate with

the Chen F-OCT Group. SEIM can detect displacement on the nanometer scale at a

kilohertz frame rate.

When coupled with a wavelength-swept laser and a

spectral disperser, SEIM can image tissue en face, explains Zhu. SEIM uses a

phase-resolved Doppler (PR-D) algorithm to measure and map the CBF within an en

face region, providing insight into the changes in CBF across tissue

surfaces.

Need for Vibration Isolation

Full

article... |

|

|

|

|

Featured Product: BM-10 Bench Top

Vibration Isolation Platform

Vertical

frequency is tunable to 0.5 Hz throughout the payload range.

- Horizontal

frequencies are weight dependent.

- Horizontal

frequency of 1.5 Hz is achieved at the upper limit of the payload range.

- At the lower

limits of the payload range the horizontal frequency is approximately 2.5

Hz.

- Vertical

frequency is tunable to 0.5 Hz throughout the payload range.

The

BM-10

bench top platform offers 10-100 times better performance than a

full size air table in a package only 4.6 inches tall and 12 inches wide and

deep. It also does this without any air or electricity! The

BM-10

bench top platform offers 10-100 times better performance than a

full size air table in a package only 4.6 inches tall and 12 inches wide and

deep. It also does this without any air or electricity!

This vibration

isolation platform is extremely easy to use and offers extreme performance. It

offers a 1.5Hz horizontal natural frequency and our signature 0.5 Hz vertical

natural frequency.

There are only two adjustments. The

BM-10

is perfect for new generations of small SPM's that require the

highest performance in a very compact system.

This is the thinnest,

smallest footprint, most portable, and most user-friendly isolator ever offered

that is capable of delivering this level of performance.They can also be made

cleanroom and vacuum capatible.

Pricing & Sizes for

MK52

|

|

|

|

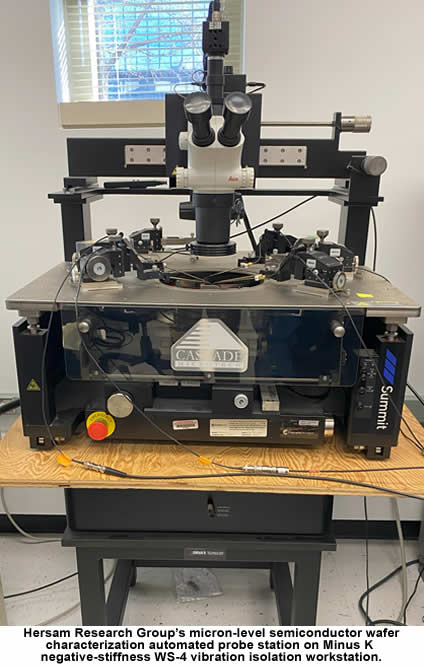

The lab has

pushed the limits of semiconductor wafer characterization in microscale

electronic devices. Facilitating this research is Negative-Stiffness vibration

isolation.

|

|

|

The Hersam

Research Group – part of the Department of Materials Science &

Engineering, McCormick School of Engineering & Applied Science, at

Northwestern University studies, develops and manipulates hybrid hard and soft

nanoscale materials for applications in information technology, biotechnology,

nanotechnology and alternative energy. The labs advanced electronic and

chemical characterization techniques provide deep insight into these areas,

with key examples including impedance spectroscopy for photovoltaics and

scanning conductive ion microscopy for lithium ion batteries. Such techniques

offer a better understanding of the key issues in enabling practical

applications of these technologies.

Micron-Level, Wafer

Characterization

Another of the groups areas of interest is

semiconductor micron-level, wafer characterization. Wafers, being a thin slice

of semiconductor, such as crystalline silicon, are used for the fabrication of

integrated circuits, and in photovoltaics, to manufacture solar cells. The

wafer serves as the substrate for microelectronic devices built in, and upon

the wafer.

During semiconductor device manufacturing, wafer testing is

performed, where all individual integrated circuits that are present on the

wafer are tested for functional defects by applying special test patterns. The

wafer testing is performed by a piece of test equipment called a wafer prober.

For electrical testing, a set of microscopic contacts or probes, called a probe

card, are held in place while the wafer, vacuum-mounted on a wafer chuck, is

moved into electrical contact.

The Hersam Research Group has developed a

digital wafer map, allowing thousands of devices to be probed in an automated

fashion.

On some of these devices we have 1,000 transistors to

characterize inside of a small sample, said William A. Gaviria Rojas, with the

Hersam Research Group. We are using an automated probe station, manufactured by

Cascade Microtech, for semiconductor micron-level, wafer scale characterization

on the devices we fabricate.

Before, the experiments were performed

with a manual probe station, taking 1 3 hours to complete. Then, the lab

switched to the automated probe station which enabled it to collect data for 2

3 days.

The manual process did not display small misalignments in the

movement of the probes over the 1 3 hour characterization, continued Rojas. But

the longer 2 3 day characterization experiments showed considerable

interruptions during high traffic times the small probes that were in contact

with the devices were losing contact.

We were looking for a vibration

isolation solution that would require low maintenance, with no additional

things like compressed air or electricity, explained Rojas. For these reasons

we selected the Minus K, Negative-Stiffness WS-4 compact vibration isolation

table.

Vibration Isolation

The Group determined that the

problem was vibration caused by people walking by, opening and closing doors

in, and near, the lab where the probe station was located. There was also

vacuum and pump equipment located in the room which created

vibration.

The probe station was positioned on top of cinder blocks,

with plastic material between. This was the extent of vibration isolation being

employed, which was inadequate.

A typical laboratory will almost always

position sensitive micron-level instrumentation on a vibration isolation

platform. Isolating such imaging equipment against low-frequency vibration has

become increasingly more vital to maintaining imaging quality and data

integrity. Indeed, the labs other Raman and AFM instrumentation all have a more

sophisticated level of vibration isolation in place.

Full

article... |

|

|

Previous

Newsletters

|

|

|

|