U.S. Tech – June 2023

Manufacturing Services

Negative-Stiffness Vibration Isolation Aids High-Resolution Microbalancing

By Jim McMahon

Materials engineering addresses the fundamental physical and chemical basis for the controlled combination of atoms to form new compounds, phases, and microstructures, as well as the characterization of the resulting structures and properties.

The ultimate goal is to optimize the performance of a material for a given design application by manipulating the structure, processing and property relationship. Forwarding this initiative is the Materials Engineering (MATE) Department at California Polytechnic State University (Cal Poly), San Luis Obispo, which is the only primarily undergraduate materials engineering program of the 53 Materials Science and Engineering departments in the United States. The MATE curriculum allows flexibility with a breadth of electives and specialization in technical electives.

MATE provides extensive hands-on experience for its students, with state-of-the-art materials characterization and testing techniques, including dynamic mechanical analysis, hardness testing, tensile testing, optical microscopy and image analysis, thermogravimetric analysis, X-ray florescence, environmental scanning electron microscopy, metallographic image analysis. Fourier-transform infrared spectroscopy, and differential scanning calorimetry.

High-Resolution Microbalancing

Supporting these precision methodologies and technologies at MATE is the need for high-resolution microbalancing. A microbalance is an instrument capable of making precise measurements of the weight of objects with relatively small mass, such as on the order of a million parts of a gram.

“We are conducting experiments on a wide variety of materials at MATE that require the use of high-resolution microbalancing,” says Trevor Harding, department chair and professor, materials engineering department at Cal Poly. “For example, right now we have researchers that are looking at magnesium oxide nanoparticles for carbon dioxide sequestration.

They think they are synthesizing magnesium oxide, and they think they are sequestering carbon dioxide, but they really don’t know that because they can’t see the particles, because these are nano-particles.

They are using a technique called Fourier-transform infrared spectroscopy (FTIR) to try to pick up magnesium carbonate signals in their samples, to determine if they are getting what they think they are getting from their synthesis.”

FTIR is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-spectral-resolution data over a wide spectral range. When IR radiation is passed through a sample, some radiation is absorbed by the sample and some is transmitted through. The resulting signal at the detector is a spectrum representing a molecular fingerprint of the sample. The usefulness of infrared spectroscopy arises because different chemical structures (molecules) produce different spectral fingerprints. FTIR is adept in assessing the formation and chemistry of polymeric molecules, as well as the molecular interactions of nanocomposites.

“To conduct this experiment looking for magnesium carbonate signals with FTIR you have to carefully measure out milligrams, and even micrograms of powder samples,” adds Harding. “This is where high-resolution microbalancing is absolutely critical in making these very-high-resolution measurements of the mass for the samples, prior to doing the characterizations.”

The high-resolution microbalance is a very important accessory piece of instrumentation for Cal Poly’s Material Engineering Department. It is also relatively sensitive instrumentation, which can be impacted by environmental vibrations inhibiting the accuracy of its performance.

“Our whole department and most of our labs are on the second floor of the building,” explains Harding. “The heating and air conditioning system is on the roof directly above our floor, so there is much mechanical vibration coming through the floor, and within the surrounding structure.”

Negative-Stiffness Vibration Isolation

MATE selected Negative-Stiffness vibration isolation, developed by Minus K Technology, an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. The company’s isolators are used by more than 300 universities.

Negative-Stiffness vibration isolators are compact, and do not require electricity or compressed air which enables sensitive instruments to be located wherever a production facility, laboratory or observatory needs to be set up, whether that be in a basement, or on a building’s vibration-compromised upper floors, or rooftop. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz vertically and horizontally (with some versions at 1.5 Hz horizontally).

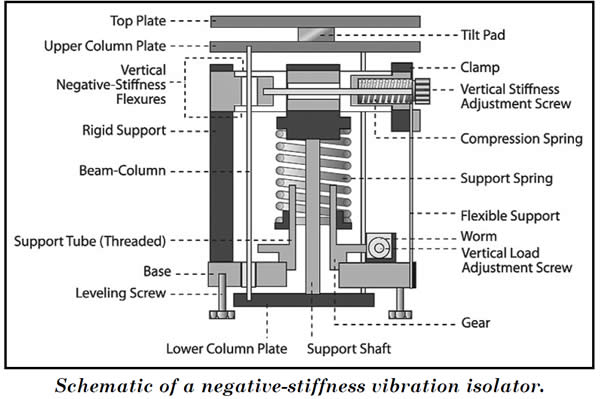

Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical motion

isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism.

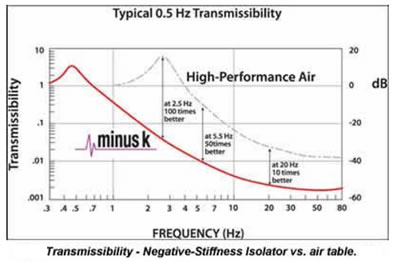

The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies. Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations.

Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz. “These vibration isolators have helped to ensure we are getting as exact results as possible from our microbalancing measurements,” concludes Harding. “We are very pleased with the resolution, and no longer are we concerned with vibration.”

Contact: Minus K Technology, Inc., 460 Hindry Avenue, Unit C, Inglewood, CA 90301, 310-348-9656 E-mail: request@minusk.com Web: www.minusk.com

|