Commercial Micro Manufacturing - September 2025

Phonon Momenta Mapping at Atomic Resolution

by Steve Varma

Advancements From Steve Varma, President, Minus K Technology

Technological advancement has been successful in miniaturizing components and structures in electronics to such a degree that they are on the order of a billionth of a meter. Central to engineering these nano-components is understanding the properties of phonons.

Mapping phonons - a quantum of energy quasiparticle associated with a compressional wave - in nanostructures is indispensable to the development and understanding of thermal nanodevices, modulation of thermal transport, and novel nanostructured thermoelectric materials. In crystals, which hold an ordered atomic structure, these phonon waves of atomic displacements tend to carry thermal energy equal to their frequency of vibration.

Through the engineering of complex structures such as alloys, nanostructures and superlattice interfaces, it is possible to alter their thermal conductivity by controlling the propagation of phonons while maintaining electrical conductivity. To achieve high phonon impedance it is optimal for nanostructures to have an abrupt change in structure which lowers their conductivity.

Studying Phonon Behavior

Utilizing an alloy of germanium and silicon, a research team consisting of UCI's IMRI, the Massachusetts Institute of Technology (MIT), and other institutions, was capable of studying how phonons tend to behave in the disordered surrounding of the quantum dot - the interface between the quantum dot and the encircling silicon, and next to the dome-shaped surface of the quantum dot nanostructure itself. Quantum dots are semiconductor particles a few nanometers in size with optical and electronic properties that differ from those of larger particles via quantum mechanical effects. They are a central topic in nanotechnology and materials science.

With the help of a Nion UltraSTEM 200 scanning transmission electron microscope (STEM), the research team has developed a novel technique to map phonons in crystal lattices at atomic resolution. To examine how phonons are distributed by the interfaces of Si/SiGe (silicon-germanium heterostructure) quantum dots, the team probed the dynamic behavior of phonons next to a single quantum dot of silicon-germanium utilizing vibrational electron energy loss spectroscopy (EELS) in the STEM at IMRI. EELS is a technique that measures the bonding environment of molecules with high spatial resolution.

"We developed a novel technique to differentially map phonon momenta with atomic resolution, which enables us to observe nonequilibrium phonons that only exist near the interface," said Dr. Xiaoqing Pan, UCI professor of materials science and engineering, and physics,

Henry Samueli Endowed Chair in Engineering, and IMRI Director. IMRI operates a wide range of state-of-the-art, open-access user facilities for the characterization of inorganic, organic and biological materials and devices, ranging from subangstrom to macroscopic length scales - available to all university, industry and non-profit researchers.

This research has allowed a deeper knowledge of the way heat tends to travel via quantum dots and engineered nanostructures in electronic components. At the atomic scale, heat is transported in solid materials as a wave of atoms that have been moved from their equilibrium position as heat shifts away from the thermal source.

"This work marks a major advance in the field because it is the first time we have been able to provide direct evidence that the interplay between diffusive and specular reflection largely depends on the detailed atomistic structure," Added Professor Pan.

Isolating Vibrations from the Nion UltraSTEM 200

UC Irvine set out to build a world-class electron microscopy facility to house the most sensitive transmission electron microscopes (TEMs) available, and to accommodate next-generation instruments expected in the coming decades. To this end, in 2015 existing ground floor engineering classrooms were converted establishing the IMRI within the UCI Samueli School of Engineering.

To mitigate noise and vibration impacts, each instrument room slab was physically isolated from the existing building structural elements and from new, adjacent walls.

At IMRI's STEM-1 room, a custom vibration isolation platform was installed to further reduce vibrations experienced by the lab's Nion UltraSTEM 200 to produce distortion free imaging at magnifications as small as sub-angstrom levels - smaller than the width of an atom. Additional preparation for the Nion UltraSTEM included recessing of the vibration isolation platform so the front section of the Nion could be rolled off and on, and the instrument could be accessed and serviced when not imaging.

IMRI selected a Negative-Stiffness vibration isolation platform, from Minus K Technology (Minus K), for its Nion UltraSTEM 200.

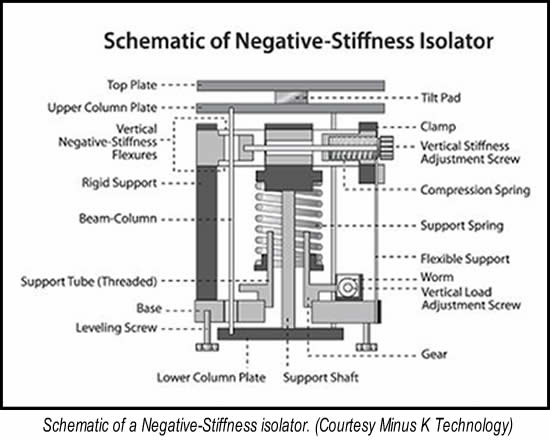

Negative-Stiffness Vibration Isolation

Negative-Stiffness vibration isolators are compact and do not require electricity or compressed air, there are no motors, pumps, or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

"Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a negative-stiffness mechanism," said Erik Runge, vice president of engineering for Minus K. "The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. The beam-columns behave as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and high internal structural frequencies."

The isolators achieve a high level of isolation in multiple directions and offer the flexibility of custom tailoring resonant frequencies to 0.5 Hz vertically and horizontally. For an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increases in the vibration frequency. The natural frequency is more commonly used to describe the system performance.

Negative-stiffness isolators deliver high performance as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz, 99 percent at 5 Hz, and 99.7 percent at 10 Hz.

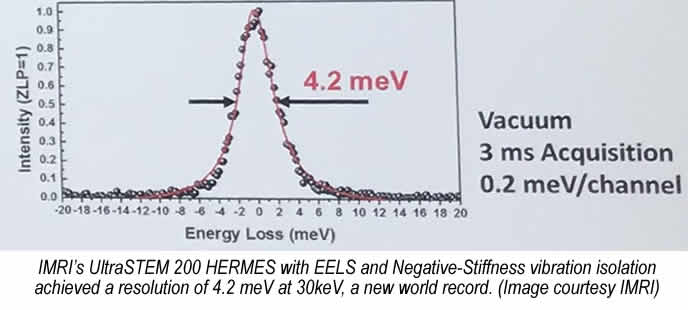

In June 2018, the inaugural International Symposium on Advanced Electron Microscopy and Spectroscopy was held during the grand opening of the IMRI. At the event, researchers used the Nion UltraSTEM 200 HERMES with EELS, supported by Negative-Stiffness vibration isolation, to achieve a resolution of 4.2 meV (millielectronvolts) at 30keV (kiloelectron volt), a new world record.

Another Research Outcome

One of the main results of IMRI's research is the development of a new method for mapping the direction of thermal carriers in materials.

"This is analogous to counting how many phonons are going up or down and taking the difference, indicating their dominant direction of propagation," explained Dr. Pan. "This technique allowed us to map the reflection of phonons from interfaces."

"We found that the SiGe alloy presented a compositionally disordered structure that impeded the efficient propagation of phonons," continued Dr. Pan. "Because silicon atoms are closer together than germanium atoms in their respective pure structures, the alloy stretches the silicon atoms a bit. Due to this strain, the UCI team discovered that phonons were being softened in the quantum dot due to the strain and alloying effect engineered within the nanostructure."

Additionally, softened phonons consist of less energy, implying that every phonon carries less heat, thereby decreasing thermal conductivity as a consequence. The softening of vibrations is behind one of the several mechanisms by which thermoelectric devices tend to hinder the flow of heat.

"Developers of thermoelectric technologies endeavor to design materials that either impede thermal transport or promote the flow of charges," said Dr. Ruqian Wu, UCI professor of physics and astronomy. "Gaining an atom-level knowledge of how heat is transmitted through solids, embedded as they often are with faults, defects, and imperfections, will aid in this quest."

About Irvine Materials Research Institute (IMRI), University of California Irvine (UCI)

The Irvine Materials Research Institute (IMRI) is an interdisciplinary special research program for materials research. As the cross-campus nexus for materials research and development, the primary mission of IMRI is to make UCI one of the world's premiere institutes for materials research.

IMRI operates a wide range of state-of-the-art, open-access user facilities for the characterization of inorganic, organic and biological materials and devices, ranging from subangstrom to macroscopic length scales - available to all university, industry and non-profit researchers. Instrumentation encompasses transmission electron microscopy (TEM), scanning electron microscopy (SEM), X-ray diffraction (XRD), elemental analysis and many other techniques, as well as laboratories for sample preparation and materials fabrication.

About Minus K Technology, Inc.

Minus K Technology, Inc. was founded in 1993 to develop, manufacture and market state-of-the-art vibration isolation products based on the company's patented negative-stiffness technology. Minus K products are used in a broad spectrum of applications including microscopy, nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft, and high-end audio. The company is an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. Minus K customers include private companies and more than 300 leading universities and government laboratories in 52 countries.

|