Number 5, December

2009

What's Here for You:

Vibration Isolation News is designed to keep our customers and friends up to date on the latest products and applications designed to facilitate better measurements and improved nanomanufacturing. We are an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other sensitive instruments, and we have users at more than 200 leading universities and private and government laboratories in 35 countries.

INDEX

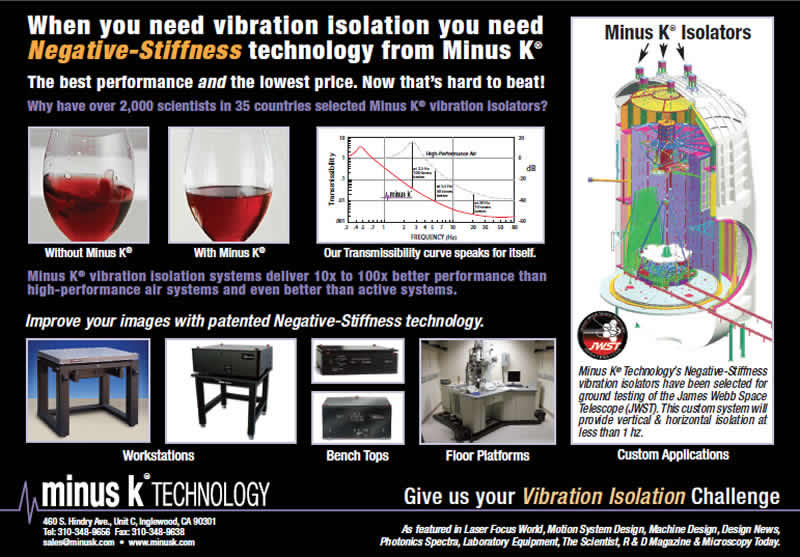

1. Minus K Selected by NASA for JWST

Testing

2. Featured

Application: Brain Waves at Georgetown Univeristy

3. Featured

Product: BM-4 Used by hundreds of customers

4. Another

Enabling Application: Improving AFM Reliability at Arizona

State University

6. Our latest Ad

5. Upcoming Nanotechnology

Meetings and Webinars

7. Your comments and suggestions

We

are proud that our negative stiffness technology is used

by some of the most quality conscious organizations in

the world. The scientists and engineers who have selected

Minus K products have done so because their work requires

the finest vibration isolation.

After considering many alternatives, ITT Space Systems,

LLC, subcontractor to Northrop Grumman Corporation (NYSE:NOC),

selected Minus K to provide vibration isolators for the

ground testing of the new James Webb Space Telescope (JWST)

at the Johnson Space Center (JSC). The JWST will be placed

in a vacuum chamber at the Johnson Space Center and supported

by a set of custom Minus K vibration isolators.

The James Webb Space Telescope is a large aperture infrared

space telescope currently planned to be launched in 2014

from Kourou, French Guiana aboard an Ariane 5 launch vehicle.

JWST is designated to succeed the Hubble Space Telescope

(HST).

A major factor in selecting Minus K is the ability to

not only isolate vibrations vertically, but also horizontally

at less than 1 Hz.

The full story can be found at: http://www.jwst.nasa.gov/

Brain

Waves at Georgetown University

'Dyeing'

to figure out how the brain works

Excerpted

from Medical Design - June 2009

Industry News

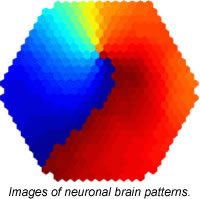

Voltage-sensitive

dye and optical recording techniques are giving neuroscientists

at Georgetown University's Department of Physiology

and Biophysics a new means for figuring out how the

brain works.

Voltage-sensitive

dye and optical recording techniques are giving neuroscientists

at Georgetown University's Department of Physiology

and Biophysics a new means for figuring out how the

brain works.

Professor Jian-Young Wu and his colleagues are conducting

research on waves of neuronal activity. They visualize

wave-like patterns in the brain cortex using a new

method called voltage-sensitive dye imaging. The dye

binds to the membrane of neurons and changes color

when electrical potential changes on the membrane

of active neurons. The neuronal sample is derived

from slices of rat neocortex.

The neocortex is the outer layer of the cerebral hemispheres

in the brain of mammals. Made up of six layers, it

is involved in higher functions such as sensory perception,

generation of motor commands and, in humans, language.

The

neurons of the neocortex are arranged in vertical structures

called neocortical columns. These are patches of the neocortex

with a diameter of about 0.5 mm and a depth of 2 mm. Each

column typically responds to a sensory stimulus representing

a certain body part, or region of sound or vision. In the

human neocortex, there are believed to be about a half-million

of these columns, each of which contains approximately 60,000

neurons.

The neocortex can be viewed as a huge web, consisting of

billions to trillions of neurons and hundreds of trillions

of interconnections. While individual neurons are too simple

to have intelligence, the collective behavior of the billions

of interneuronal interactions occurring each second can

be highly intelligent.

Traditionally, scientists have studied brain activity by

placing a few electrodes in the brain and measuring the

electrical signals of the neurons close to the electrodes.

This method is workable for understanding the function of

the cortex and interactions between individual neurons,

but it is not suitable for studying the emerging properties

of the nervous system.

"It is like viewing a few pixels on a television screen

and trying to figure out the story," explains Wu. "Now,

with optical methods and voltage-sensitive dyes, we can

visualize the activation in a large area of the neocortex

when the brain is processing sensory information, similar

to watching the whole television screen."

"Voltage-sensitive dye is a compound that stains neuronal

membrane and changes its color when the neuron is excited,"

continues Wu. "This allows us to visualize population

neuronal activity dynamically in the cortex. We study how

individual neurons in the neocortex interact to generate

population neuronal activities that underlie sensory and

motor processing functions. Population activities are composed

of the coordinated activity of billions of neurons. Currently,

we study how oscillations and propagating waves can be generated

by small ensembles of neocortical neurons."

Viewing the spatiotemporal patterns of neuronal population

in the cortex is markedly different from recording individual

neurons. Here the cortical activity is viewed as "population

activity," which can be more complex than the linear

addition of an individual neuron's activity. Voltage-sensitive

dye and optical recording techniques give the neuroscientist

new tools for figuring out how brain cortex works.

Wu's imaging team has uncovered spiraling wave patterns

resembling little hurricanes in the brain. He believes that

this hurricane-like spiral pattern is an emergent behavior

of the network.

"A metrological hurricane is an emergent behavior of

a large volume of air molecules," says Wu. "If

you were to dissect a hurricane into individual air molecules

you would not find any special process that generates a

hurricane. Similarly, in the nervous system, spiral waves

are an emergent process of the neuronal population and there

might be no special cellular process attributed to spirals."

However, like a hurricane, spiral waves can be a powerful

force. Their power is seen when it comes to organizing the

activity of a neuronal population. Spirals generated in

a small area can send out a powerful storm that invades

large, normal brain areas and starts a seizure attack. This

hypothesis means that epilepsy could be viewed not just

as "mis-wiring" in the brain, but as an abnormal

wave pattern that invades normal tissue.

Similarly, during cardiac fibrillation, spiral waves form

in the heart emitting rotating and scroll waves in two and

three dimensions. As a leading life-threatening situation,

these rotating waves can kill the patient instantly as the

pumping function of the heart is disrupted by the 5 to 10

Hz rotations, which drives chaotic and abnormally rapid

cardiac contractions.

Wu believes that propagating waves are a basic pattern of

cortical neuronal activity, and that these wave patterns

may play an important role in initiating and organizing

brain activity involving millions to billions of neurons.

Studying the spatiotemporal patterns of neuronal population

activity may provide insight into normal brain functions

and pathological disorders. This research has the potential

to help scientists understand abnormal waves that are generated

in the brains of patients with epilepsy.

Since voltage-sensitive dye signals are small - a change

of 0.1 to 1.0 percent of the illumination intensity - Wu's

team uses a high-dynamic-range camera, photodiode array

to detect the voltage- sensitive dye signals of the cortical

activity. The photodiode array can resolve extremely small

changes in light, usually one part of ten thousands. (Human

eyes and ordinary digital cameras register light changes

of one part to a hundred). Detecting such small signals

requires an extreme isolation of vibration. The lab had

to contend with low frequency vibrations from air conditioning

equipment, people walking, and wind blowing against the

building. Vibrations as low as 1 Hz were inhibiting the

integrity of the images and data.

"At first, we used high quality air tables, but they

were not adequate for isolating low frequency vibrations,"

says Wu. "We tried putting a second air table on top

of the first one, but that still did not give us the isolation

we needed. Then we tried an active, electronic system, but

we were still spending much time fighting with floor vibrations.

We were dealing with an unresolved vibration problem for

many years."

The Georgetown lab eventually tested, and settled upon negative-stiffness

mechanism vibration isolation systems from Minus K Technology,

Inglewood, CA, (www.minusk.com) which enabled the lab to

get vibration isolation down to a level of 1 Hz. This effectively

cancelled out any vibration noise difficulties that were

inhibiting image and data readings.

Within the past 10 years, Wu's team has documented a variety

of waveforms (e.g., plane wave and spirals) in brain slices

during artificially induced oscillations. Using neocortical

slices and mathematic models they are studying the initiation

of the waves and the factors that control their propagating

direction and velocity.

The negative-stiffness vibration isolation system are also

used by the lab in the development of optical imaging techniques

such as imaging propagating waves in vivo, within intact

brains. "This is technically difficult," says

Wu. "Other imaging methods (MRI, PET or MEG) provide

inadequate spatiotemporal resolution. Large scale neuronal

activity is a hallmark of a living brain. We hope to visualize

the waves in the cortex in vivo during sensory processes

and in animals while behavioral and cognitive tasks are

performed."

The full

article can be found at: https://minusk.com/content/in-the-news/medical_design_june_2009.html

Featured Product: BM-4 Bench Top Vibration Isolation Platform

The

BM-4 is one of our most popular products. It is the most

cost effective bench top platform capable of 1/2 Hz performance

vertical and horizontal.

Applications have included the full spectrum from Scanning

Probe Microscopes (AFM, STM, NSOM, etc) and Laser/Optical

systems through neurosciences, electronics, and even audio

reproduction.

Because Minus K products can be used under vacuum conditions

and require no power or air for their operation, they

have been used in applications ranging from ground tests

of spacecraft to sensitive experiments where there can

be no stray electromagnetic fields.

Minus K's BM-4 Bench Top Vibration Isolator

Typical

transmissibility curve with 1/2 Hz natural Frequency

| Load Capacities (approximate): | ||

| Model | Payload Range* | Price** |

| 25BM-4 | 0 - 25 lb : (0 - 11 kg) | $2,750 |

| 50BM-4 | 20 - 55 lb : (9 - 25 kg) | $2,805 |

| 100BM-4 | 50 - 105 lb : (23 - 48 kg) | $2,860 |

| *Contact Minus K for custom payload ranges. |

**For International Orders, A Handling Fee

of 5% is Added. |

|

Performance:

- Vertical natural frequency of 1/2 Hz or less can be achieved over the entire load range.

- Horizontal natural frequency is load dependent. 1/2 Hz or less can be achieved at or near the nominal load.

Negative-stiffness

isolators have resonant frequencies at 0.4 to 0.5 Hz, compared

to 2.3 Hz for pneumatic systems. They transmit less energy

from low-frequency vibrations to the payload than do pneumatic

systems, and maintain better isolation performance through

building frequencies to about 100 Hz.

https://minusk.com/content/products/standard/bm-4.html

Improving

AFM data reliability in nanoelectronics research,

Utilizing negative-stiffness vibration isolation

Excerpted from Electronic Products

& Technology - September 2008

Products on Review

Arizona

State University Nanostructures Research Group, led by ASU

Regents' Professor and nanoelectronics pioneer, David K.

Ferry, Ph.D., M.S.E.E., B.S.E.E., utilizes negative-stiffness

vibration isolation technology to more efficiently eliminate

ultra-low environmental frequencies and improve data set

integrity in nanoelectronics AFM research.

It was

not until Long after 1977 that the name nanoelectronics

came into use, but Dr. David K. Ferry was already actively

engaged in developing some of the world's smallest transistors.

The field, called "Ultra-Small Devices" in the

later part of the 1970's, was in its infancy and Dr. Ferry's

research team was one of only four select groups around

the world aggressively researching the limits of small electronic

devices.

Today, Dr. Ferry heads up the Nanostructures Research Group

at Arizona State University (ASU) in Tempe, a collection

of faculty, staff and students working on research in the

regimes of nanolithography, and the physics of nanostructures

and ultra-small semiconductor devices. The group is part

of the University's College of Engineering, Center for Solid

State Electronics Research, whose alumni makes up a serious

constituency throughout the nanoelectronics universe, in

both industry and academia.

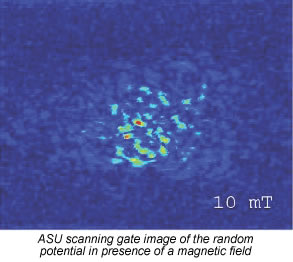

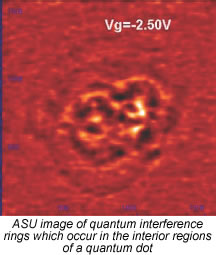

Their

current interests lie in the area of quantum dots,

quantum wires and ultra-small semiconductor devices

in a variety of materials. The group conducts a

wide spectrum of theoretical studies of quantum

transport in these very small devices. For example,

they are doing a process called scanning gate microscopy

at low temperatures. This involves taking the equivalent

of an atomic force microscope and putting bias on

it and studying the change in conductance of small

semiconductor structures as they move this bias

tip around on a surface.

Their

current interests lie in the area of quantum dots,

quantum wires and ultra-small semiconductor devices

in a variety of materials. The group conducts a

wide spectrum of theoretical studies of quantum

transport in these very small devices. For example,

they are doing a process called scanning gate microscopy

at low temperatures. This involves taking the equivalent

of an atomic force microscope and putting bias on

it and studying the change in conductance of small

semiconductor structures as they move this bias

tip around on a surface.

Their

system is mounted in a large cryogenic cooler, an

enclosed container with a helium-3 cooling system,

an isotope of a helium molecule - which is brought

down to 300-milli-Kelvin, or 1,000-times below room

temperature, about one-half degree above absolute

zero. The cooler has a vacuum jacket around it so

the heat can't transmit in, and it protects the cold

from being mitigated by the ambient room temperature.

The Atomic Force Microscope (AFM) tip is on a cantilever. Normally, with the AFM, you just move this cantilever along the surface then note the change in position as it goes over topography on the surface. Dr. Ferry's group is utilizing a process called a piezo-electric sensor. They metalicize the AFM cantilevered tip with a very thin layer of metal so they can apply a voltage to it - then use that voltage to perturb the structure they are looking at. As the tip moves it creates a voltage across the plane, which is measured to determine certain mechanical property values. This is a technique that was developed at Harvard four to five years ago.

This type of experimentation is not uncommon, similar experiments are being done by a large number of universities. But what is not common, is the system that the Nanostructures Research Group is using for vibration isolation: negative-stiffness vibration isolation, developed by Minus K Technology (www. minusk.com) - which provides a significantly greater and more stable attenuation of the critical lower vibration frequencies, and therefore more reliable accrued data sets.

When measuring a very few angstroms or nanometers of displacement, you have got to have an absolutely stable surface upon which to rest your instrument. If you do not, any of that vibration coupled into the mechanical structure of your instrument will cause vertical noise, and fundamentally an inability to measure these kinds of high resolution features.

"Any kind of vibration noise in the system makes that AFM cantilever tip move, and that gives you bad signals and incorrect data," says Dr. Ferry. "We actually went further than most university applications because we integrated a rather large magnet into our system, something that Harvard, for example, is just now putting into their operation. The magnet allows us to look at different types of transport. We can turn the magnet on and look at the magneto-transport of the semiconductors. It is a quite a different mode of transport altogether."

"The

entire system had to be isolated, not just the cantilever,"

continues Dr. Ferry. "We required an extremely

high level of vibration isolation given our research

parameters. We are deriving modern electronic devices

from our experiments. Future electronic devices

are our interest. What we are doing is looking at

the conductivity of materials and then seeing how

quantum mechanics fits into this. We study basic

physics which has a real application - engineering

- and particularly in the semiconductor industry.

Our research covers:

"The

entire system had to be isolated, not just the cantilever,"

continues Dr. Ferry. "We required an extremely

high level of vibration isolation given our research

parameters. We are deriving modern electronic devices

from our experiments. Future electronic devices

are our interest. What we are doing is looking at

the conductivity of materials and then seeing how

quantum mechanics fits into this. We study basic

physics which has a real application - engineering

- and particularly in the semiconductor industry.

Our research covers:

(1) Electron beam lithography of quantum dots and

quantum devices, with applications such as quantum

ballistic transport at very low temperatures and

high magnetic fields, as well as the quantum-classical

transition, and the role of quantum effects in real

devices at room temperature."

"(2)

Magneto-transport studies used to probe the nature

of electron dynamics in semiconductor quantum dots,

which are quasi-zero-dimensional structures whose

size is comparable to the Fermi wavelength of the

electrons themselves. Magneto-transport studies

may be used to probe these phenomena and to determine

the factors which limit electron phase coherence

within the structures. Current interest in these

devices is motivated by their potential application

in new areas of technology, such as quantum computing

and ultra high frequency signal processing."

"(3) Surface chemical analysis performed with a scanning

Auger microprobe. Under good conditions, a lateral resolution

of about 25 nm is achievable."

"(4)

Professor Michael Kozicki, in the group, has examined

Chemically Enhanced Vapor Etching (CEVE) patterning

technique. He has used hydrocarbon contamination

layers from laboratory air or vacuum chamber ambients

and successfully demonstrated nanoscale pattern

formation in silicon dioxide. He has also developed

a nitrogen chamber coupled directly to a UHV STM/AFM

facility for CEVE processing of silicon dioxide

resists and their use in semiconductor device fabrication.

Within the nitrogen chamber there is a processing

system for the actual CEVE development."

"(4)

Professor Michael Kozicki, in the group, has examined

Chemically Enhanced Vapor Etching (CEVE) patterning

technique. He has used hydrocarbon contamination

layers from laboratory air or vacuum chamber ambients

and successfully demonstrated nanoscale pattern

formation in silicon dioxide. He has also developed

a nitrogen chamber coupled directly to a UHV STM/AFM

facility for CEVE processing of silicon dioxide

resists and their use in semiconductor device fabrication.

Within the nitrogen chamber there is a processing

system for the actual CEVE development."

"But, the current work with the scanning probe

system is really interesting, and made possible

by the negative-stiffness isolators," says

Dr. Ferry."

The

negative-stiffness isolator is a passive isolation

approach, and has a key advantage in that it is

not powered. It has no electricity going to it.

So, in a site where heat buildup could be an issue,

such as with enclosed cryogenic chambers, negative-stiffness

becomes a highly efficient option.

Negative-stiffness

isolators employ a unique - and completely mechanical -

concept in low-frequency vibration isolation. Vertical-motion

isolation is provided by a stiff spring that supports a

weight load, combined with a negative-stiffness mechanism

(NSM). The net vertical stiffness is made very low without

affecting the static load-supporting capability of the spring.

Beam-columns connected in series with the vertical-motion

isolator provide horizontal-motion isolation. The horizontal

stiffness of the beam-columns is reduced by the 'beam-column'

effect. (A beam-column behaves as a spring combined with

an NSM.) The result is a compact passive isolator capable

of very low vertical and horizontal natural frequencies

and very high internal structural frequencies. The isolators

(adjusted to l/2Hz) achieve 93% isolation efficiency at

2 Hz, 99% at 5 Hz, and 99.7% at l0 Hz.

Negative-stiffness isolators provide a capability quite

unique to the field of nanotechnology - specifically,

the transmissibility of the negative-stiffness isolator.

That is, the vibration that transmits through the isolator

as measured as a function of floor vibrations - which

is substantially improved over active isolation systems.

Although active isolation systems have fundamentally

no resonance, their transmissibility does not roll off

as fast as negative-stiffness isolators. So, at building

and seismic frequencies the transmissibility of active

isolators can be 10X greater than negative-stiffness

isolators. This causes substantial adverse measurement

and imaging artifacts in the data.

Negative-stiffness isolators provide a capability quite

unique to the field of nanotechnology - specifically,

the transmissibility of the negative-stiffness isolator.

That is, the vibration that transmits through the isolator

as measured as a function of floor vibrations - which

is substantially improved over active isolation systems.

Although active isolation systems have fundamentally

no resonance, their transmissibility does not roll off

as fast as negative-stiffness isolators. So, at building

and seismic frequencies the transmissibility of active

isolators can be 10X greater than negative-stiffness

isolators. This causes substantial adverse measurement

and imaging artifacts in the data.

Compared to other laboratory research instrumentation,

the growth of AFM usage has been quite extensive over

the past 10-years. AFM equipment placement has gone

through a doubling phase pretty much every year during

the last decade. Since its inception in 1988, it has

continuously proven to be a key tool in moving nanotechnology

research forward.

"More than half of the universities in the United States

and worldwide, are engaging in nanotechnology research,"

says Dr. Ferry. "In the electronic area, the nanoelectronic

side of it has been going since the late 1960's. This is

driven by the fact that in the semiconductor industry all

things are getting smaller and smaller. Today, the transistors

have critical dimensions down around 25 nanometers. And

the most critical dimension is the oxide thickness which

is 1 nanometer. When you consider that you have to control

one nanometer vertical thickness over 300-millimeters of

lateral dimension, that is a difference of 10 to the 8th

power. That defines what modern manufacturing technology

produces. The need for effective vibration isolation has

never been greater, and will continue to become more demanding

as the nano-industry progresses."

The

full article can be found at:

https://minusk.com/content/in-the-news/electronic_products&technology_september_2008.html

This ad will be featured in Photonics Online and The Acoustical

Society of America (JASA)

Upcoming Meetings and Webinars:

| Meeting: | Sponsor: | Dates: | Location: |

| SPIE Photonics West | Visit Minus K Booth #5020 at this exhibit | Jan.

26, 2010 - Jan. 28, 2010 |

San Francisco, CA |

| http://spie.org/x2584.xml | |||

| Nanotechnology 10 | WSEAS, IARAS, IASME | Feb.

20, 2010 - Feb. 22, 2010 |

Cambridge, UK |

| http://www.wseas.us/conferences/2010/cambridge/nanotechnology/ | |||

| ICONN 2010 International Conference on Nanoscience and Nanotechnology | Australian Institute of Physics | Feb.

22, 2010 - Feb. 26, 2010 |

Sydney, Australia |

| http://www.ausnano.net/iconn2010/ | |||

| NSTI Nanotech 2010 | Nano

Science and Technology Institute Visit the Minus K Booth at this exhibit |

Jun.

20, 2010 - Jun. 24, 2010 |

Anaheim, CA |

| http://www.techconnectworld.com/Nanotech2010/ | |||

Comments/Suggestions: Applications in New Fields or Features of Interest to You in Our Next Newsletter:

If you want

to share your application with our readers, please send us a description

so that we can publish it in an upcoming newsletter. If you have

comments or suggestions we would be very interested to read them.

Please send any materials to: david.resnik@minusk.com

Tel: 310-348-9656 Fax: 310-348-9638

Contact Us www.MinusK.com

© Minus K Technology Inc., Vibration Isolation Systems. All rights reserved.