|

|

Newsletter October 2023 | Menu of Newsletters

| |

|

This Cal Poly Case

Study was a wnining submission in

Minus K 's 2016

Educational

Giveaway.

Cal Poly’s

2D solid experiment: A self-made interfacial shear rheometer of the two

circular coils that create magnetic forces to deform the sample material in a

glass dish and measured by the microscope suspended above, all sitting on a

Minus K 100BM-1 negative-stiffness vibration isolator.

|

Vibration Isolation Supports the Search

for Memory in Soft, Amorphous Solids

The Soft Mechanics Laboratory at California

Polytechnic State University (Cal Poly is researching soft, amorphous solids

like foams, concentrated emulsions and bulk metallic glasses to determine

whether these materials remember deformations that were applied repeatedly in

the past, and how this information could be encoded in their microscopic

structure and behaviors.

Nathan Keim, Assistant Professor of

Physics at Cal Polys Soft Mechanics Laboratory in San Luis Obispo, has for well

over a decade been conducting research on memory, self-organization and other

non-equilibrium behaviors of soft materials under deformation.

This

includes experimental studies of the mechanisms of plasticity in disordered

solids, and liquid interfaces. With his students, the lab conducts experiments

on interfacial materials, made up of microscopic particles adsorbed at an

oil-water interface, using these two-dimensional systems as models of soft,

amorphous solids like foams, concentrated emulsions and bulk metallic

glasses.

Amorphous solids like foam, sand, and ice cream feature many

particles crowded together. Each particle is fully constrained by its

neighbors, but the material is disordered so these constraints vary greatly,

said Professor Keim. When the material is put under sufficient stress, we know

that local groups of particles rearrange by squeezing past one another, but the

way these microscopic processes organize and give rise to macroscopic behaviors

of the material is still not well understood.

We focus on deformations

that are large enough to cause these rearrangements and change the material,

but too small to disrupt the material completely and cause it to start flowing.

explained Professor Keim. This creates the possibility that the material can

retain a detailed memory of how it was deformed in the past. Exploring how

these memories are stored and how they can be retrieved is an opportunity to

learn more about the mechanisms at play when these materials

deform.

Interfacial Shear Rheometer and Managing Vibrations

To

facilitate this research, Professor Keim and his team have constructed an

instrument, a kind of interfacial shear rheometer, which allows a

two-dimensional amorphous solid to be deformed while measuring its mechanical

properties.

The apparatus uses a pair of magnetic coils to move a

magnetized needle embedded in the material, deforming the material with pN

(piconewton) forces. By simultaneously recording the motion of tens of

thousands of particles in the material, they can connect what is happening on

the microscopic and macroscopic scales a rare and highly desirable ability in

the study of materials.

Since our research basically takes place on the

surface of a dish of water, the experiment is especially sensitive to

low-frequency vibrations that excite surface waves and agitate the material

under study, added Professor Keim. The building where the physics department,

and the Soft Mechanics Lab is housed, has severe vibrations at 5 Hz due to the

many fume hoods in the building, as well as the HVAC system.

When these

vibrations are too strong, they do not just introduce noise, but actually

trigger rearrangements of the particles within the sample material essentially

altering the sample during the measurement. Even when they do trigger

rearrangements, low-frequency disturbances also add noise to the mechanical

measurements and limit the ability to deform the material precisely and

repeatedly

For vibration isolation, the experiments were being conducted

on a tabletop platform resting on passive balloon isolators. But this was not

sufficient to dampen vibrations satisfactorily. So the lab began performing

experiments at night when the chemistry fume hoods were not in operation, which

helped mitigate the problem, but still required considerable computer

processing afterwards to stabilize imaging.

These vibration limitations

had grown more important as we began to examine our materials response when the

exact same deformation is applied hundreds of times, in order to study the

possibility of learning and memory effects, continued Professor

Keim.

Having looked at both optical air tables and active vibration

cancellation systems as potential solutions for the vibration problem, and

determined that neither was satisfactory for cancelling vibrations at very low

frequencies, the lab selected Negative-Stiffness vibration

isolation.

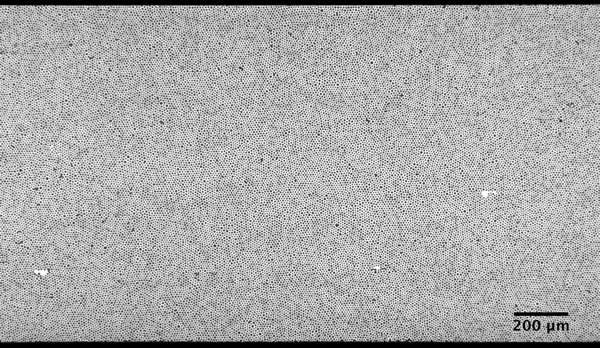

2D solid material

sample: A layer of polystyrene particles at the interface between oil and

water. The black bars at the top and bottom are the boundaries that are moved

to shear the material.

|

| |

Article

continued...

|

|

|

|

The

LC-4

is an ultra compact, low-frequency negative-stiffness isolator. It comes in two

configurations, our low horizontal frequency performance of 1.5 Hz or our ultra

low horizontal frequency performance of 0.5 Hz. Both configurations offer our

signature 0.5 Hz vertical natural frequency.

This low frequency

vibration isolator is for weight loads from 15 to 130 lbs. and 1/2 Hz

performance vertical and horizontal.

LC-4

isolators can be combined into multi isolator systems to support heavier

payloads while taking up very little room themselves. The isolators are

passive, manually-adjustable and require no air or electricity.

More...

- Vertical natural

frequency of 1/2 Hz or less can be achieved over the entire load range.

- Horizontal natural

frequency is load dependent. 1 1/2 Hz (low horiz. freq.) or 1/2 Hz (ultra low

horiz. freq.) or less natural frequencies can be achieved at or near the

nominal load.

- See

performance

for a typical transmissibility curve with 1/2 Hz natural frequency.

Pricing &

specs for LC-4

|

| |

|

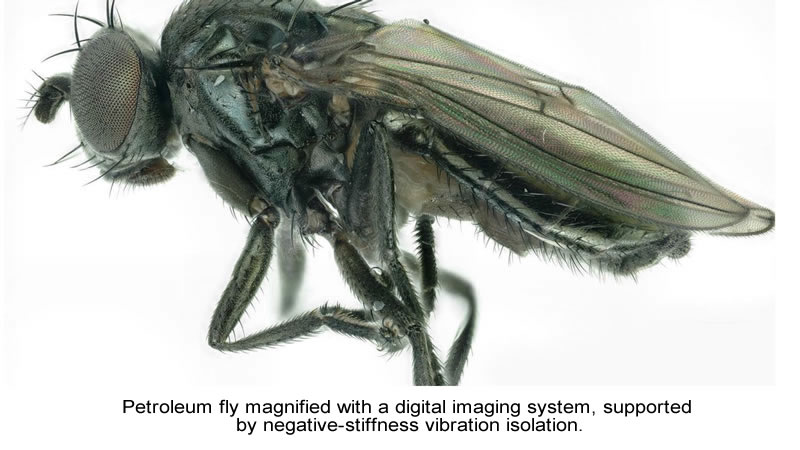

Vibration

Isolation Improves Specimen Examination at the

Natural History Museums of

Los Angeles County

The museums'

microscope is supported by negative-stiffness vibration isolation, which

enables precise clarity of specimens being viewed at high magnification and

high resolution

|

The Natural History Museums of Los Angeles County

(NHMLAC), which include the Natural History Museum in Los Angeles' Exposition

Park, the La Brea Tar Pits, and the William S. Harding Museum, is the largest

natural and historical museum in the western United States, holding one of the

world’s most extensive and valuable collections of natural and cultural

history—more than 35 million specimens and artifacts covering 4.5 billion

years of history.

The NHMLAC collections are strong in many fields, but

the mineralogy and Pleistocene paleontology collections are among the most

impressive, the latter thanks to the wealth of specimens collected from the La

Brea Tar Pits located in the heart of Los Angeles. The worlds most powerful

gateway to the Ice Age, the asphalt seeps at the La Brea Tar Pits represent the

only active urban fossil dig site in the world. The site contributes an ongoing

wealth of extraordinary specimens, like saber-toothed cats, mammoths, dire

wolves, and mastodons, as well as the tiny microfossils of insects, plants,

mammals, and reptiles from the last 50,000 years. |

|

Fundamental to the activities of NHMLAC is

research. Essentially, close examination of these objects, artifacts, and

specimens for the purposes of illustration, preparation of scientific papers

for publishing, and photography for displays within the museum. Much of this

research is conducted with the use of microscopy, viewing specimens at high

magnification and high resolution to observe and examine fine

details.

Researchers at the Natural History Museum in Exposition Park,

for example, are examining the structure of prehistoric fish teeth, minerals,

insects, and other small creatures, said Brian Brown, PhD, curator of the

Entomology Section. Even ancient feathers from 100 million years ago encased in

amber. Amber influences clarity and distorts and changes the viewability of the

feathers. Very high microscopy resolution is needed to examine minute, fine

details from these and other specimens..

|

|

For the examination of its specimens, the museum uses

a digital microscope.

Digital microscopes incorporate observation, image

capture, and measurement capabilities while providing an on-screen interface

for viewing objects. Compared to conventional optical microscopes, digital

microscopy provides superior imaging capabilities. Even at higher

magnification, images are fully focused due to a large, depth- of-field

composition function.

The digital imaging system gives us up to 1,000

times magnification, continued Brown. The microscope allows us to view great

detail and fidelity in our specimens.

Vibration problem

For

several years ambient vibrations severely plagued the microscopes ability to

deliver precision images.

At high magnifications things get very

sensitive, added Brown. This requires great stability. But our microscope is

located on the third floor of the Entomology Section in the museum, in a

cantilevered room extending from the main building. An elevator is located

right next to the room, so we were constantly dealing with vibration issues

that were affecting the quality of our images. We would wait for periods of

relative stability, like between elevator movement, to view images. Even if the

elevator was not running, we would still get ambient vibrations from people

walking around in the department.

Vibration can be caused by a multitude

of factors within a building. Every structure is transmitting noise. Within the

building itself the heating and ventilation system, fans, pumps, compressors,

elevators, doors closing, and footfall are just some of the sources that create

low-frequency vibration that will affect microscopy imaging and data sets.

Depending on how far away the microscopy instrumentation is from these

vibration sources, and where in the structure the instrumentation is

locatedwhether in a basement or in a cantilevered roomwill determine how

strongly the instrumentation will be influenced.

External to the

building, sensitive instrumentation can be influenced by vibrations from truck

movement, road traffic, nearby construction, loud noise from aircraft, and even

wind and other weather conditions that can cause movement of the

structure.

Essentially, we were getting so-so results from the

microscope, and we knew the problem was coming from the ambient vibrations in

the room, explained Brown. We tested an active cancellation vibration isolation

system, but found it hard to set up, and it really did not cancel vibrations

very well. We then did a demonstration of a negative- stiffness passive

vibration isolation system and found it to perform very well.

Article

continued...

|

|

|

|

|

|

|

|

|