|

|

Newsletter November 2022 | Menu of Newsletters

|

Microscopy News (Legacy Article

Aug2017)

Superionic Solid Electrolytes for Next-Generation Lithium

Batteries: Negative-Stiffness Vibration Isolation Facilitates

Nano-Research

Full article and larger

images...

Advances in materials testing techniques have enabled

scientists and engineers to measure mechanical properties, and observe and

characterize mechanical phenomena that control deformation and failure down to

nearly the atomic level. One field that is benefiting from such advances in

testing techniques is energy storage. The option of creating higher energy

capacity batteries has direct implications on

performance with

laptops, smartphones, and electric vehicles. Many of the

rechargeable batteries used in these portable devices and vehicles are

lithium-ion (Li-ion), composed of two electrodes, a positive electrode made of

lithium and a negative electrode made of graphite, and a chemical electrolyte.

The tremendous capacity of lithium and the metals ability to move lithium ions

and electrons in and out of an electrode as it cycles through charge and

discharge, make it a well suited anode material.

The electrolyte

chemically contains the electric charge and also acts as the medium through

which the current flows between electrodes when the battery is connected in a

circuit. As the electrolyte in a Li-ion battery also contains a solution of

lithium, the lithium electrode tends to react with this medium, causing

dendrite fibers to form over the course of battery charge and discharge cycles,

particularly when the battery is cycled at a fast rate. These fibers move out

from the electrode and into the electrolyte, where they break down the

controlled path that the electrons generally take by producing conductive paths

haphazardly throughout the structure. This can result in a rapid discharge that

allows excess current to flow,

causing the battery

to fail prematurely. It can also unsafely heat up the

battery to a point where it can generate fire.

To realize significant

improvements in energy density, vehicle range, cost requirements, and safety,

the use of metallic lithium anodes will likely be required for powerful

next-generation rechargeable battery chemistries like lithium-air and

lithium-sulfur. However, the use of metallic lithium with liquid and polymer

electrolytes is limited due to dendrite formation, and

efforts to solve this

problem have met with limited success.

Researching Pure

Lithium and Superionic Solid-State Electrolytes

An

alternative approach is being pursued at Michigan Technical Universitys

Department of Materials Science and Engineering, Small-Scale Mechanical Testing

Laboratory, in collaboration with Oak Ridge National Laboratory and the

University of Michigan. The research focuses on a pure lithium anode accessed

through, and protected by a superionic solid-state electrolyte that would

prevent side reactions and enable safe, long-term, and high-rate cycling

performance.

Our lab is focused on the mechanical characterization

of small volumes of materials, said Erik G. Herbert PhD, Assistant Professor,

Department of Materials Science and Engineering, Michigan Technical University.

We are trying to understand how materials like metals, ceramics, polymers,

composites, and biomaterials respond when their boundaries are mechanically

loaded. We perform experiments relating to characteristics such as elasticity

and hardness, to probe the properties of these materials.

The key risk

and current limitation of Li-ion technology is the gradual loss of lithium over

the cycle life of the battery, said Dr. Herbert. In particular, losses caused

by physical isolation from roughening, dendrites or delamination processes, or

to chemical isolation from side reactions. To abate these problems we endeavor

towards a much deeper analysis of the degradation processes and a predictive

understanding of the lithium-metal solid electrolyte interface as a function of

cycling.

Specifically, we need to understand how the lithium is

gradually consumed, why the interfaces are surprisingly resistive, how the

electrolyte eventually fails, how defects in the lithium migrate, agglomerate

or anneal with further cycling or time, continued Dr. Herbert. And

additionally, whether softer electrolytes can be used without incursion of

lithium dendrites, and what effects processing and fabrication have on the

interface performance.

Among the efforts being pursued to answer these

questions,

state-of-the-art

small-scale mechanical characterization techniques are being

carried out at Michigan Technical University to provide the critical

information that will directly enable transformative insights into the complex

coupling between the microstructure, its defects and the mechanical behavior of

both lithium and the solid-state electrolytes.

Nanoindentation

Studies

In addition to an extensive array of optical and

electron microscopes, atomic force microscopes and x-ray diffraction

instruments accessible through the universitys Applied Chemical and

Morphological Analysis Laboratory, the Small-Scale Mechanical Testing

Laboratory operates a versatile suite of six small-scale mechanical testing

platforms in which the user has direct control over the way the test is

performed and how the raw data are recorded, reduced, and analyzed...

Full

article...

|

|

Featured Product: BM-10 Bench Top Vibration Isolation

Platform

- Horizontal frequencies are weight dependent.

- Horizontal frequency of 1.5 Hz is achieved at the upper

limit of the payload range.

- At the lower limits of the payload range the horizontal

frequency is approximately 2.5 Hz.

- Vertical frequency is tunable to 0.5 Hz throughout the

payload range.

The

BM-10 bench top platform offers 10-100 times better

performance than a full size air table in a package only 4.6 inches tall and 12

inches wide and deep. It also does this without any air or

electricity! The

BM-10 bench top platform offers 10-100 times better

performance than a full size air table in a package only 4.6 inches tall and 12

inches wide and deep. It also does this without any air or

electricity!

This vibration isolation platform is extremely easy to use

and offers extreme performance. It offers a 1.5Hz horizontal natural frequency

and our signature 0.5 Hz vertical natural frequency.

There are only two

adjustments. The

BM-10 is perfect for new generations of small

SPM's that require the highest performance in a very compact

system.

This is the thinnest, smallest footprint, most portable, and

most user-friendly isolator ever offered that is capable of delivering this

level of performance.They can also be made cleanroom and vacuum

capatible.

Pricing & Specifications

|

| |

|

|

Give us your Challenge

|

Pricing |

Get a Quote |

|

Announcing the 2020 Minus K

Technology Educational Giveaway to U.S. Colleges and

Universities

Minus K Technology, Inc. is giving away $25,000* worth

of patented vibration isolators to colleges within the United

States.

Your college could receive one of our superior performing

negative-stiffness low-frequency vibration isolators, which use no air or

electricity and are currently being used for biology, neuroscience, chemistry,

crystal growing, physics, audio reproduction and many other fields.

If

you have an Atomic Force Microscope (AFM), Electron Microscope, Interferometer,

Laser Optical System, Micro Hardness Tester, or any other special equipment

that would be assisted by our vibration isolation, simply complete the giveaway

submission form and send it back to edgiveaway@minusk.com. If you're one of the

top applicants, we'll send you one of these free vibration isolators to assist

you with your research.

more...

|

|

|

|

October 2018 Legacy Article: When built

into inspection equipment, like a coordinate measuring machine, a laser

interferometer system reports the surface condition of a product with more

accuracy than any other method. Such a precision laser-position measurement

system allows users to improve product quality and reliability, and increase

manufacturing consistency and production yields.

|

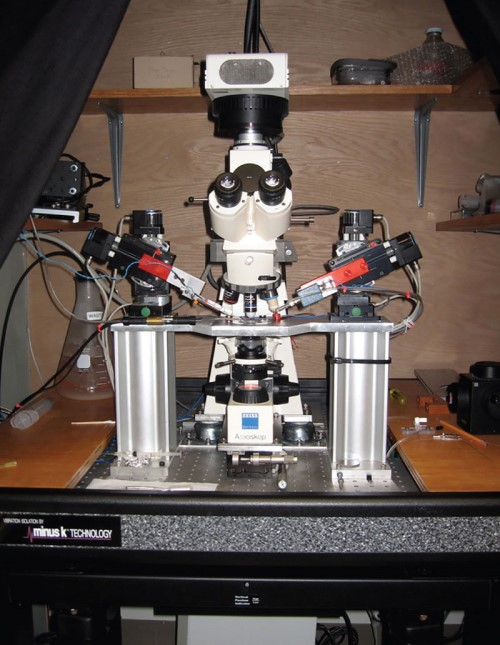

(High Resolution Microscopy Workstation,

Mounted on a Minus K Vibration Isolation Platform)

|

Micro- and nano-level microscopy, whether used in

academic laboratories or industry, is susceptible to vibrations from the

environment, requiring these instruments to employ vibration isolation systems.

When measuring a very few angstroms, nanometers, or microns of displacement, an

absolutely stable surface must be maintained to support the instrument. Any

vibrations that are transferred into the mechanical structure of the instrument

will cause vertical and horizontal noise, compromising data sets and limiting

the ability to measure high resolution features.

Traditionally, air

tables have been the isolators used for microscopy equipment. The ubiquitous

passive-system air tables, adequate up until a decade ago, are now being

seriously challenged by the need for more refined imaging requirements. Air

systems provide limited isolation vertically and very little isolation

horizontally. Yet, high-resolution microscopy demands vibration isolation

requirements that are unparalleled in both the vertical and horizontal axes.

This has posed a significant challenge for many researchers.

CENTER

FOR LEARNING AND MEMORY

Such was the case with the Center for Learning

and Memory (CLM), part of the Department of Neuroscience at the University of

Texas at Austin, a multi-disciplinary group studying the mechanisms governing

the processes of learning and memory in animals.

Research in one of the

CLM laboratories is primarily directed to understanding the cellular and

molecular mechanisms of synaptic integration and long-term plasticity of

neurons in the animal medial temporal lobe. The lab focuses attention on the

hippocampus, subiculum, and prefrontal cortex areas of the brain that play

important roles in learning and memory. These regions are also of interest

because they have a low seizure threshold and are implicated in several forms

of human epilepsy

Neurons are electrically excitable cells that process

and transmit information through electrical and chemical signals in a process

known as neurotransmission, also called synaptic transmission. The fundamental

process that triggers the release of neurotransmitters is the action potential,

a propagating electrical signal that is generated by exploiting the

electrically excitable membrane of the neuron.

VIBRATION

PROBLEM... Full article...

|

|

|

|

|

November 2010 Legacy Article: Minus K

Technology's compact, high-capacity, low-frequency negative-stiffness isolator

is designed to support heavy payloads while reducing low-frequency vibrations.

The

LC-4 isolator comes in

several capacity ranges to match vibration-sensitive instruments for weight

loads from 1 to 130 lbs. The LC-4 comes in two versions (low-frequency

horizontal and ultra-low-frequency horizontal). Both versions can deliver a

vertical natural frequency of 0.5 Hz or less, which can be achieved over the

entire load range. Horizontal natural frequency is load dependent. The

low-frequency version has a 1.5-Hz natural frequency, while the

ultra-low-frequency version can achieve 0.5 Hz or less near the nominal

loads.

|

|

The need for precise vibration isolation with

scanning probe microscopy (SPM) and nearfield scanning optical microscopy

(NSOM) systems is becoming more critical as resolutions continue to bridge from

micro to nano. Whether used in academic labs or commercial facilities, SPM and

NSOM systems are extremely susceptible to vibrations from the environment.

When measuring a very few angstroms or nanometers of displacement,

an absolutely stable surface must be established for the instrument. Any

vibration coupled into the mechanical structure of the instrument will cause

vertical and/or horizontal noise and bring about a reduction in the ability to

measure high-resolution features. The vertical axis is the most sensitive

parameter for SPMs, but these instruments can also be quite sensitive to

vibrations in the horizontal axis.

Lab design teams obviously need to

plan for these special equipment requirements, as they make decisions

regarding building-level isolation techniques and localized techniques.

Traditionally, bungee cords and high-performance air tables have been the

vibration isolators most used for SPM and NSOM work. The ubiquitous

passive-system air tables, adequate until a decade ago, are now being

challenged by the more refined imaging requirements. Bench-top air systems

provide limited isolation vertically and very little isolation horizontally.

Also at a disadvantage are active isolation systems, known as

electronic force cancellation, which use electronics to sense motion and then

implement equal amounts of motion electronically to compensate and cancel out

the motion. Active systems are somewhat adequate for applications with lasers

and optics, since they can start isolating as low as 0.7 Hz. But because they

run on electricity, they can be negatively influenced by problems of electronic

dysfunction and power modulations, which can interrupt scanning.

Lately, the introduction of integrated microscopy systems employing

multiple scopes is enabling more complex optical measurements, but these

systems are also much heavier, and there has been little vibration-isolation

technology available for such heavy instrumentation. Air tables, which have

been liberally used for optics applications, are not ideal for these nano-scale

resolution systems because of their inability to effectively isolate vibrations

below 20 Hz. Nor can active systems be used with these newer combination

systems because of their inability to handle heavy instrumentation.

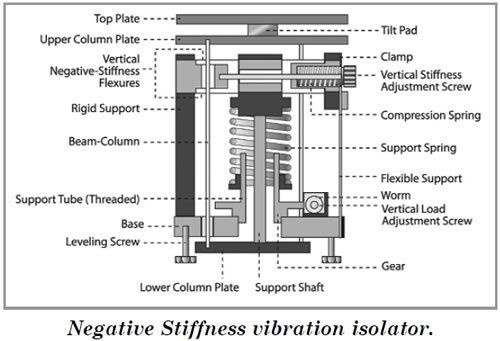

Negative-stiffness mechanism (NSM)

vibration isolation offers a viable alternative choice for SPM

and NSOM systems. This includes applications using atomic force microscopy

(AFM) integrated with micro-Raman spectroscopy, where negative-stiffness

vibration isolation is particularly well-adapted. In fact, it is the

application of negative-stiffness isolation that has enabled AFMs to be truly

integrated with micro-Raman. Negative-stiffness isolators can handle the weight

of a combined system, as well as isolating the equipment from low-frequency

vibrations: a critical set of factors that high-performance air tables and

active systems cannot achieve. The neuronal sample is derived from slices of

rat neocortex.

|

|

|

|

Negative-Stiffness Vibration

Isolation Aids Quantum Electronic Research

Single-Atom Flakes &

Quantum Electronics Vibration Isolation |

|

Better understanding the character and properties

of graphene, and similar two-dimensional materials, will advance their

integration into improvements for semiconductors, electronics, photovoltaics,

battery energy storage and many other applications.

One university laboratory that has been

conducting research with graphene and other atomically-thin materials for some

years is the Henriksen Research Group at Washington University in St. Louis,

Missouri.

Our experiments entail the careful measurement of the

electronic properties of thinly-layered materials, including both electronic

transport and thermodynamic quantities, such as the magnetization and

compressibility of electron gas, says Professor Erik Henriksen Ph.D., leading

professor of the Henriksen Research Group. We also conduct measurements of the

infrared absorption spectrum to probe the electronic structure directly.

The group searches for unusual and unexpected properties of

low-dimensional materials, utilizing a combination of electronic, optical and

thermodynamic measurement approaches to understand the novel quantum electronic

phases that arise. The experiments are generally conducted at very low

temperatures, fractions of a degree Kelvin above absolute zero, and in high

magnetic fields, employing custom devices made of graphene or related

crystals.

Single-Atom Flakes

We look at the physics of the

layered graphene, where the layers are weakly bound, so they can be pulled

apart, explains Henriksen. We isolate these very thin layers down to a single

atom. Then, lift the graphene flakes from bulk graphite with adhesive tape,

transferring them very carefully onto silicon wafers.

Full article...

|

|

|

In its continuing efforts to revolutionize

discovery-based research into complex biological systems, Pacific Biosciences

has released its next generation of automated, long-read genomic sequencer with

single molecule, real-time (SMRT) sequencing technology – the Sequel

System.

In its continuing efforts to revolutionize

discovery-based research into complex biological systems, Pacific Biosciences

has released its next generation of automated, long-read genomic sequencer with

single molecule, real-time (SMRT) sequencing technology – the Sequel

System.

The Sequel System is very multifaceted in operation, says Kevin

Lin, mechanical engineer at Pacific Biosciences. It encompasses robotics,

chemical and biological processing, and photonics. Because its intended to be

used in diverse settings within research and laboratory environments, excessive

ambient vibrations could negatively influence the data sets. So, we needed to

implement a vibration isolation component that not only isolated the sensitive

components from vibrations, but also was sufficiently small, compact, and

integrative.

Internal and external factors can create vibration issues

from buildings housing the system including heating and ventilation systems,

fans, pumps, elevators, adjacent road traffic, nearby construction, loud noise

from aircraft, and weather conditions. These influences cause vibrations as low

as 2Hz that can create strong disturbances in sensitive equipment.

With

our earlier sequencer model, we used air tables for vibration isolation, which,

for the most part, performed adequately, Lin says. But use of the Sequel System

in more diverse locations, where low-frequency vibrations may be present to a

greater or lesser degree, necessitated a vibration isolator that was compact

enough to fit into our much smaller Sequel System and could effectively cancel

out these low-frequency vibrations.

Negative-stiffness vibration

isolation

Pacific Biosciences ultimately decided on negative-stiffness

isolation to address their needs. Developed by Minus K Technology,

negative-stiffness isolators use completely passive mechanical technology for

low-frequency vibration isolation without using motors, pumps, or chambers,

making them zero maintenance. Because of their very high vibration isolation

efficiencies, particularly in the low frequencies, negative-stiffness vibration

isolation systems enable vibration- sensitive instruments, such as the Sequel

System, to operate in severe low-vibration environments that wouldnt be

practical with top-performance air tables and other vibration-mitigation

technologies...

Full article...

|

|

MInus K's Assist with the

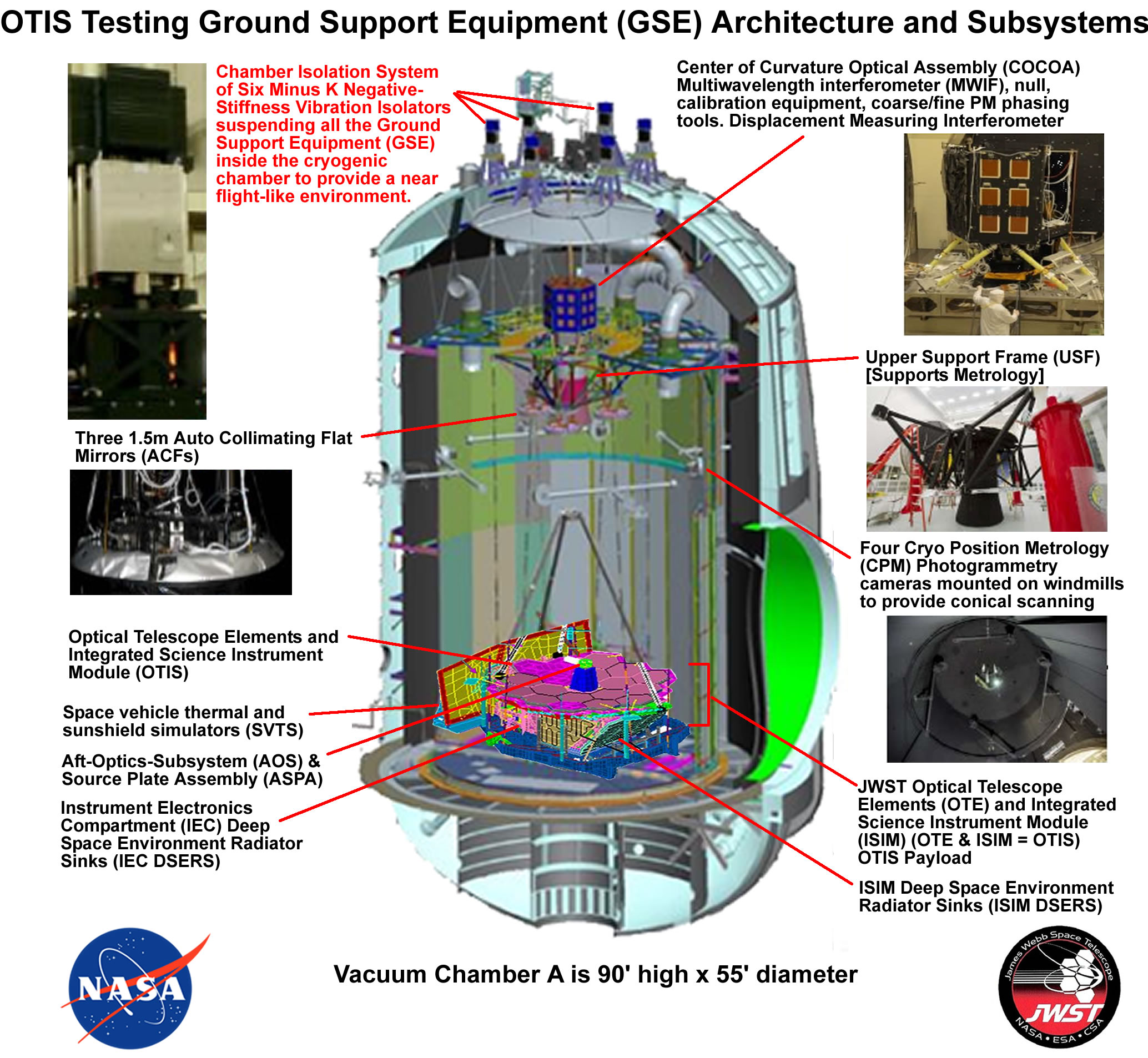

Building of the JWST Telescope

|

|

All of the JWST systems-level cryogenic vacuum

tests were performed at the NASA Johnson Space Center’s (JSC) Chamber-A.

It is now the largest high-vacuum, cryogenic-optical test chamber in the

world, and made famous for testing the space capsules for NASA's Apollo

mission, with and without the mission crew. It is 55 feet (16.8 meters) in

diameter by 90 feet (27.4 meters) tall. The door weighs 40 tons and is opened

and closed hydraulically. The air in the chamber weighs 25 tons, when all the

air is removed the mass left inside will be the equivalent of half of a staple.

Diagram of the Cyrogenic Chamber in which the JWST

was tested for space.

For three years, NASA JSC engineers built and

remodeled the chambers interior for the temperature needed to test the James

Webb Space Telescope. Chamber A was retrofitted with the helium shroud, inboard

of the existing liquid-nitrogen shroud and is capable of dropping the chambers

temperature farther down than ever, which is 11 degrees above absolute zero (11

Kelvin, -439.9 Fahrenheit or -262.1 Celsius).

A key addition to Chamber

A was the addition of a set of six custom Minus K negative-stiffness

vibration isolators. The Minus K passive isolators do not require air and

offer better isolation than air and active isolation systems. A major factor in

the selection of the of the vibration isolators was that they not only isolate

vibration vertically, but also horizontally at less than 1 Hz.

JWST was

designed to work in space where the disturbances are highly controlled and only

come from the spacecraft, while on Earth with all the ground-based

disturbances, such as the pumps and motors, and even traffic driving by can

affect the testing. The Minus K vibration isolators provided dynamic isolation

from external vibration sources to create a near flight-like disturbance

environment.

The isolators utilize Minus K's patented Thermal

Responsive Element (TRE) compensator device, a passive mechanical device,

requiring no air or electricity just like the isolators. The TRE compensator

adjusted the isolators as the temperature changes throughout the testing at

JSC, keeping the JWST in the proper position.

The Critical Design Review

for Spacecraft-to-Optical Telescope Element vibration isolation system was

completed one month earlier than scheduled at the end of 2011. The six Minus K

negative-stiffness vibration isolators were installed on top of Johnson Space

Centers Thermal Vacuum Chamber A in March 2014.

JWST needed a support

structure inside the vacuum chamber to hold equipment for the testing.

Engineers installed a massive steel platform suspended from the six vibration

isolators via steel rods about 60 feet long (18.2 meters) each and about 1.5

inches (or 38.1 mm) in diameter, to hold the telescope and key pieces of test

equipment. The sophisticated optical telescope test equipment included an

interferometer, auto-collimating flat mirrors, and a system of photogrammetry

precision surveying cameras in precise relative alignment inside the chamber

while isolated from any sources of vibration, such as the flow of nitrogen and

helium inside the shroud plumbing and the rhythmic pulsing of vacuum

pumps.

Minus K's Involvement

continued...

-How much

farther can JWST see than the Hubble?

-Why was

it launched from near the equator?

-How cold

does the JWST get in space?

-How did

origami play into the trip?

-Why

24-karat gold on the mirrors?

Full article...

|

|

Our 29th

Anniversary is on 2/1/22

See the Milestones & Timeline

1993-2022

Press Release:

New Ultra-Thin

CT-2 Low-Frequency

Vibration Isolation Platform Adapts

to Space Constraints in Critical Micro-

and Nano-Microscopy

(replaces the CT-1)

Full

release... |

|

|

|

|

|