|

|

Newsletter June 2022 | Menu of Newsletters

|

|

Give us your Challenge

|

Pricing |

Get a Quote |

NASA's ICESat-2 Spacecraft relies

with testing using Minus K vibration isolation

Inside a thermal vacuum chamber. No

electrical cords required.

|

|

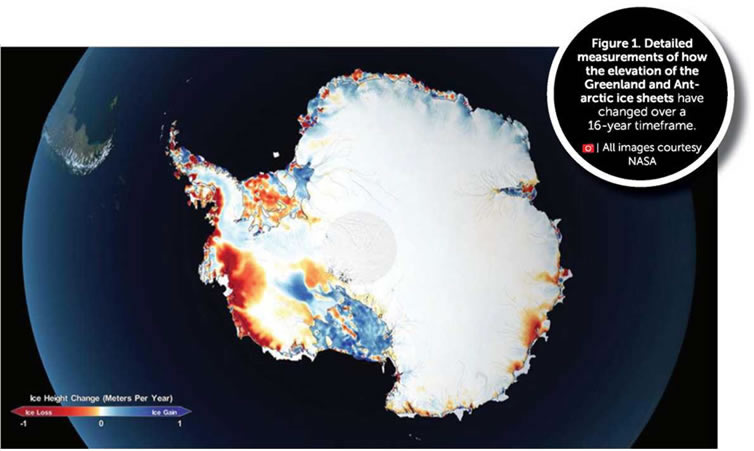

NASA’S Ice, Cloud and Land Elevation

Satellite-2 (ICESat-2), which lifted off three years ago, has generated a

comprehensive portrait of the complexities of ice sheet change and insights

into the future of Greenland and Antarctica. The ICESat-2 measurements, when

compared to the measurements taken by the original ICESat from 2003 to 2009,

showed that in Antarctica the ice sheet is getting thicker in parts of the

continent's interior, likely as a result of increased snowfall. But the massive

loss of ice from the continent's margins (due to ocean warming) far outweighs

any small gains in the interior.

|

ICESat-2 will measure ice

heights in the polar regions

|

"The new analysis reveals the ice sheets'

response to changes in climate with unprecedented detail, revealing clues as to

why and how the ice sheets are reacting the way they are," said Alex Gardner, a

glaciologist at NASA's Jet Propulsion Laboratory."

This is one of the

first times that researchers have used laser altimetry to measure loss of the

floating ice shelves around Antarctica simultaneously with loss of the

continent's ice sheet. The researchers found ice shelves are losing mass in

West Antarctica, where many of the continent's fastest-moving glaciers are

located. Patterns of thinning over the ice shelves in West Antarctica show that

Thwaites and Crosson ice shelves have thinned the most, an average of about

16-ft and 10-ft of ice per year, respectively.

In this technique, AFM

tips or sharp needles can be employed to transfer small, femtoliter volumes of

molecular solutions, or other liquid-based ink, to predefined locations on the

surface of samples.

|

|

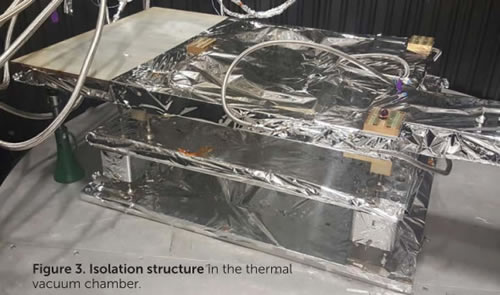

The vacuum chamber was configured with four

vacuum compatible Minus K 800CM-1CV negative-stiffness vibration

isolators to support the ATLAS instrument for the thermal vacuum testing. "The

Minus K isolators' primary use was inside the thermal chambers which did not

have as stable of a mounting surface as we would have liked," said Brian

Simpson, mechanical lead for ATLAS testing. "The isolators were critical in

cancelling out jitter introduced into our system by the facility."

Full article...

|

|

|

|

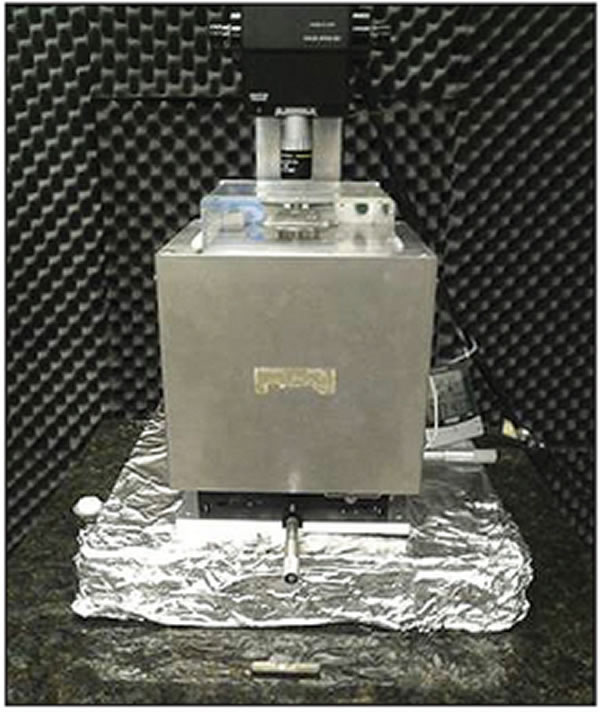

Compact CM-1 Low Frequency

Vibration Isolator

The

CM-1: is a

compact high capacity, low-frequency negative-stiffness isolator. As with all

Minus K isolators, they are completely passive and use no air or electricity.

The isolators can be combined into multi isolator systems to support heavy

payloads while taking up very little room themselves.

- Dimensions: 7.875" W x 7.875" D x 8.5" H (200mm W x

200mm D x 216mm H)

- Vertical natural frequency of 1/2 Hz or less can be

achieved over the entire load range.

- Horizontal natural frequency is load dependent. 1/2 Hz

or less can be achieved at or near the nominal load.

CM-1

Video

More...

Pricing & sizes for

CM-1

Specifications

(pdf)

|

|

|

Give us your Challenge

|

Pricing |

Get a Quote |

Sunken Treasure (2000 year old

Ancient Roman lead ingots)

Surrounding The Coldest Cubic Meter In The

Universe

Suspension of the cryostat uses

three Minus K Negative-Stiffness vibration isolators

Case Study |

|

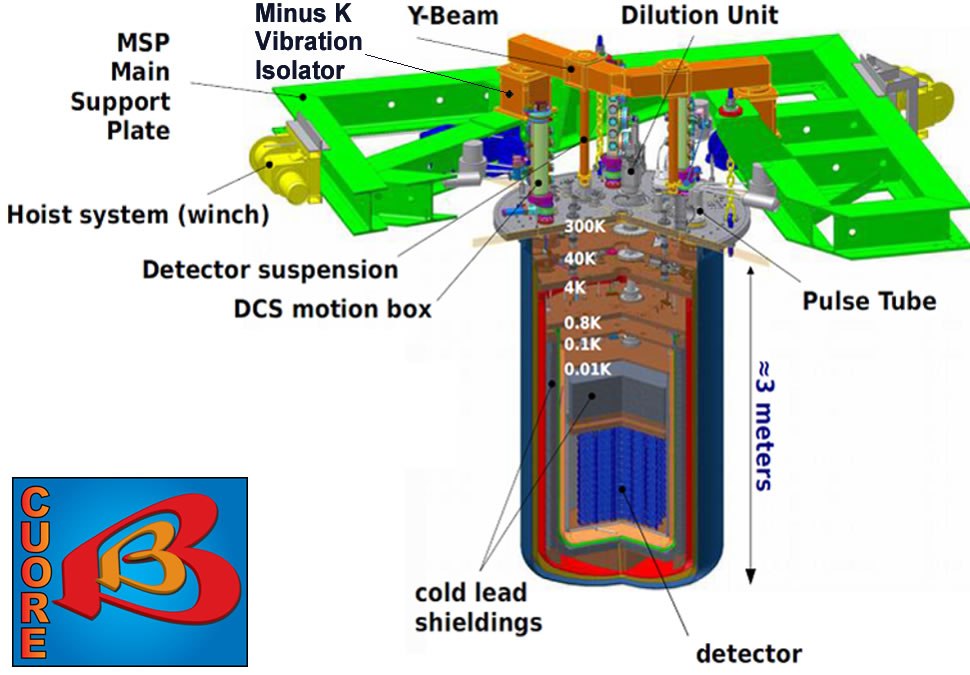

November 2017 Legacy Article: The

Cryogenic Underground Observatory for Rare Events (CUORE) is a 1-ton scale

bolometric experiment that will examine a property of ghostly neutrinos by

looking for a phenomenon called neutrinoless double beta decay. Revealing this

process could be a clue as to why there is more matter than antimatter in the

universe and show that neutrinos get their mass in a way thats different from

all other particles.

Unlike ordinary beta decays, in which electrons and

antineutrinos share energy, the neutrinoless double beta decay produces two

electrons, but no neutrinos at all. It is as if the two antineutrinos that

should have been produced annihilate one another inside the nucleus.

|

The Cryogenic Underground

Observatory Cryostat

|

The cryostat consists of six nested vessels and

shields. The three outermost ones are included in the outer Cryostat. Two of

them (300 K and 4 K) are vacuum tight: the space between the 300 K and 4 K

vessels constitutes the Outer Vacuum Chamber (OVC) of the cryostat and the 300

K vessel operates at room temperature. The volume inside the 4 K vessel

represents the Inner Vacuum Chamber (IVC) and in normal running condition this

vessel is thermalized to 4 K. Between the 300 K and 4 K vessel there is a

thermal radiation shield at 40 K covered with a multi-layer aluminized

superinsulation.

The entire cryostat is suspended from a heavy steel

support structure, Main Support Plate (MSP) which bears the load of close to 20

tons, specifically the detector (~1 ton), thermal shields and flanges (~8 tons)

and the internal lead shielding (~10 tons).

The detector suspension has

been designed to minimize the transmission of mechanical vibrations both due to

seismic noise and to the operation of cryocoolers and pumps. The suspension is

a two stage low-frequency isolator fixed to a Y-beam above the cryostat, in the

vertical direction, and a pendulum with a natural frequency of about 0.4Hz, in

the horizontal direction. It must provide load path for the detector while

minimizing the heat input and the vibration transmission.

The suspension

is made up of three Minus K Negative-Stiffness vibration isolators and

the Y-beam positioned on top of them which is mounted on top of the Main

Support Plate (MSP). The detector is suspended by the Ybeam through three

composite rods. The system formed by the Minus K isolators and the rest of the

detector will behave like a spring-mass system with a cut-off frequency of

0.5Hz. The composite rods are be made of several 316LN stainless steel rods,

with three copper thermal links connecting to 40K, 4K and Still plates. Also to

minimize vibrational noise of the detector as much as possible there are

independent suspensions for the vessels, dilution unit, and detector.

|

|

|

University of California

Merced Relies on

Negative Stiffness Vibration Isolator

from Minus K

Technology

For

accurate research into microscale friction

Case Study |

| |

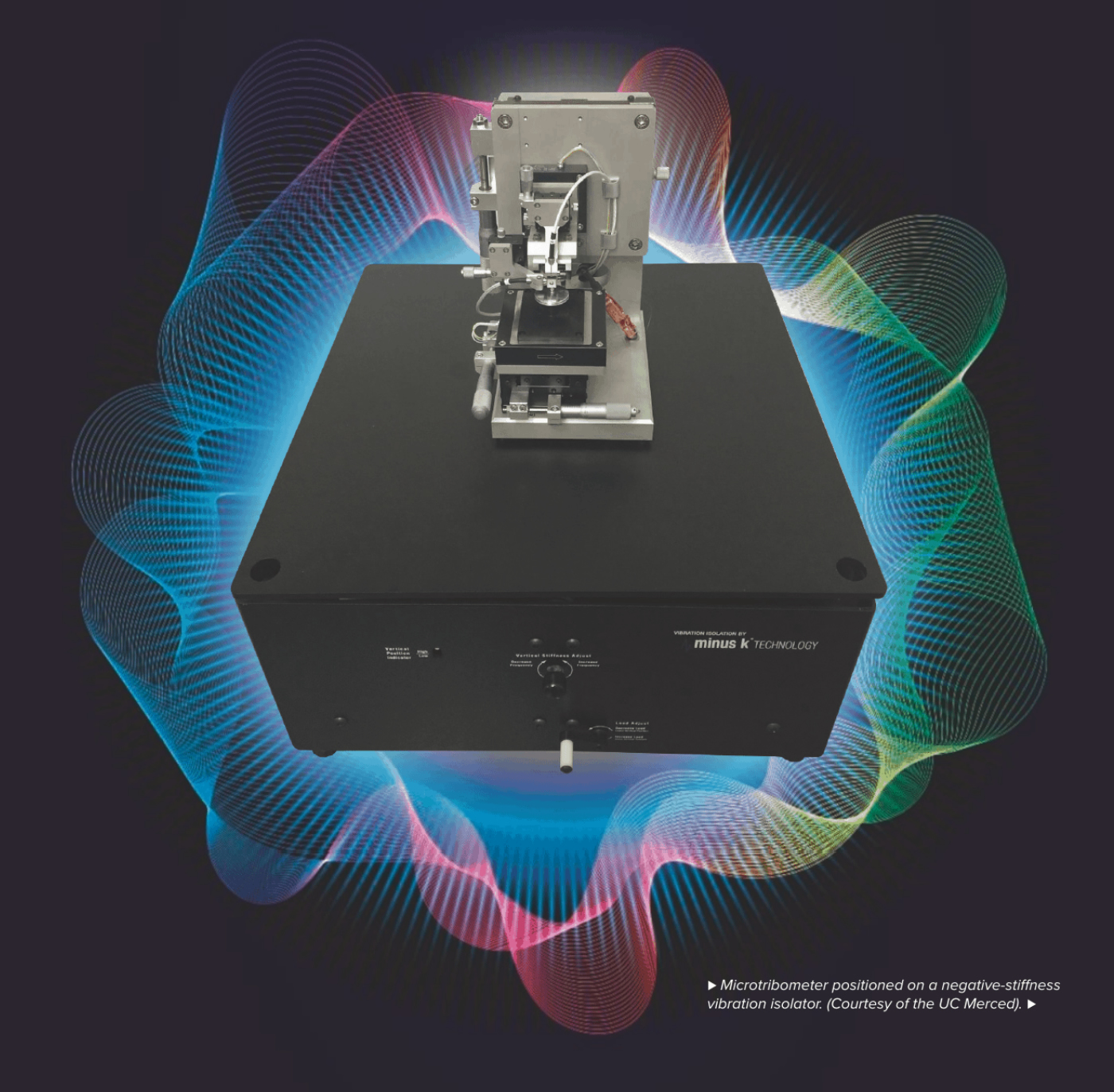

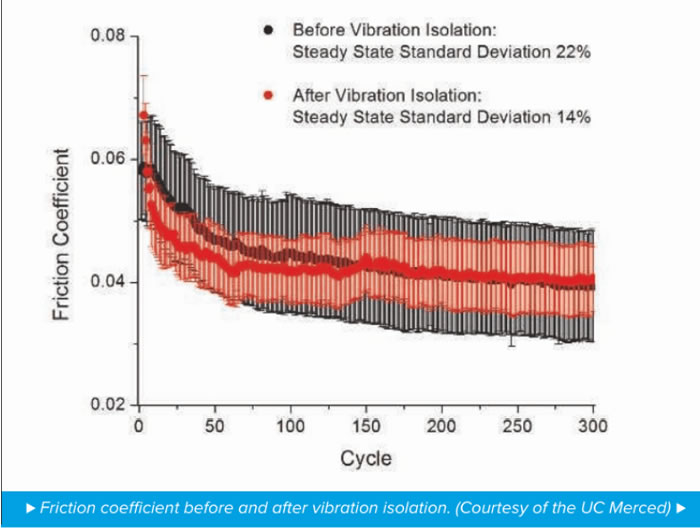

Feb.2022 -- Elizabeth Valero, Editor CMM

Magazine: Welcome to the first issue of 2022, which, it goes without

saying, we all hope will be a significantly more positive year than the

previous two. CMM has got off to a good start, with articles expected from new

as well as old faces in the coming months, and I like to think this Is a sign

of our continuance on the road back to normality.

First I thought I

might highlight a case study on how a negative-stiffness vibration isolator

from Minus-K Technology has enabled the School of Engineering at the University

of California Merced (UC Merced) to isolate environmental vibrations and thus

obtain precision microscale or, more specifically, micronewton friction

measurements The school has been using a linear-reciprocating microtribometer

to conduct valuable research into friction and wear on different material

surfaces subjected to various loading and sliding speed conditions. In order to

acquire measurements at (he micron level the microtribometer needs to be

isolated from environmental vibrations, particularly very low hertz vibrations,

these can be due to many factors from equipment and people inside the building

to vehicles and construction noise outside of it.

The negative-stiffness

vibration isolator replaced the vibration isolator the school initially used

for its research but that proved inadequate. This is because the

microtribometer demanded greater vibration Isolation for the measurement of

friction in micronewtons. The ability of the negative-stiffness vibration

isolator 1o achieve a significantly higher level of vibration isolation means

The researchers can be confident that the friction response measured is

attributable to the microtribometer's sliding contact. Moreover, they are able

to study materials that have much lower frictions.

|

Microtribometer on a Miinus K

Negative Stiffness Vibration Isolator (Courtesy of the UC Merced)

|

The School of Engineering at the University of

California Merced (UC Merced) has been engaged In research focusing on

applications of microscale friction measurements to better understand

fundamental mechanisms underlying tribological phenomena. A critical end

fundamental component of the school's research Is the Isolation of

environmental vibrations utilizing a negative-stiffness vibration isolator from

Minus K Technology which has enabled precision measurements of friction at

micronewton magnitudes.

Whenever two surfaces are moving in contact with

each other their behavior is influenced by friction. Smooth surfaces, even

those polished lo a mirror finish, are not truly smooth on scales. They are

rough, with sharp or rugged projections referred to as

asperities.

Initially, the surfaces only touch at a few of these

asperity points which cover only a very small portion of the surface area.

Friction and wear originate at these points, so understanding their behavior

becomes important when studying materials in contact.

The measurement of

this fractional force between two surfaces is undertaken using a

microtriborneter This instrument measures quantities, such as coefficient of

friction and friction force between the two surfaces that are in contact These

measurements can relate to a number of types of important properties of

mechanical components, including energy efficiency.

The basic operation

of a microtribometer involves a flat of spherical surface that is moved

repetitively across the face of another material. An exact load is applied to

the moving part for the duration of the test. Equipment and methods used to

examine the surfaces before and after sliding include optical microscopes,

scanning electron microscopes, optical interferometers and mechanical roughness

testers. The final measurements show the wear on the material end are often

used to determine its strength and longevity.

The need for vibration

isolation

Microtribometer measurements at the micron level require

isolation from ambient environmental vibrations, particularly very low hertz

vibrations. Isolating a laboratory s sensitive instrumentation against

low-frequency vibrations has become increasingly more vital to maintaining

imaging quality and data Integrity.

|

|

|

Negative-Stiffness Vibration

Isolation Aids Quantum Electronic Research

Single-Atom Flakes &

Quantum Electronics Vibration Isolation |

|

Better understanding the character and properties

of graphene, and similar two-dimensional materials, will advance their

integration into improvements for semiconductors, electronics, photovoltaics,

battery energy storage and many other applications.

One university laboratory that has been

conducting research with graphene and other atomically-thin materials for some

years is the Henriksen Research Group at Washington University in St. Louis,

Missouri.

Our experiments entail the careful measurement of the

electronic properties of thinly-layered materials, including both electronic

transport and thermodynamic quantities, such as the magnetization and

compressibility of electron gas, says Professor Erik Henriksen Ph.D., leading

professor of the Henriksen Research Group. We also conduct measurements of the

infrared absorption spectrum to probe the electronic structure directly.

The group searches for unusual and unexpected properties of

low-dimensional materials, utilizing a combination of electronic, optical and

thermodynamic measurement approaches to understand the novel quantum electronic

phases that arise. The experiments are generally conducted at very low

temperatures, fractions of a degree Kelvin above absolute zero, and in high

magnetic fields, employing custom devices made of graphene or related

crystals.

Single-Atom Flakes

We look at the physics of the

layered graphene, where the layers are weakly bound, so they can be pulled

apart, explains Henriksen. We isolate these very thin layers down to a single

atom. Then, lift the graphene flakes from bulk graphite with adhesive tape,

transferring them very carefully onto silicon wafers.

Full article...

|

|

|

In its continuing efforts to revolutionize

discovery-based research into complex biological systems, Pacific Biosciences

has released its next generation of automated, long-read genomic sequencer with

single molecule, real-time (SMRT) sequencing technology – the Sequel

System.

In its continuing efforts to revolutionize

discovery-based research into complex biological systems, Pacific Biosciences

has released its next generation of automated, long-read genomic sequencer with

single molecule, real-time (SMRT) sequencing technology – the Sequel

System.

The Sequel System is very multifaceted in operation, says Kevin

Lin, mechanical engineer at Pacific Biosciences. It encompasses robotics,

chemical and biological processing, and photonics. Because its intended to be

used in diverse settings within research and laboratory environments, excessive

ambient vibrations could negatively influence the data sets. So, we needed to

implement a vibration isolation component that not only isolated the sensitive

components from vibrations, but also was sufficiently small, compact, and

integrative.

Internal and external factors can create vibration issues

from buildings housing the system including heating and ventilation systems,

fans, pumps, elevators, adjacent road traffic, nearby construction, loud noise

from aircraft, and weather conditions. These influences cause vibrations as low

as 2Hz that can create strong disturbances in sensitive equipment.

With

our earlier sequencer model, we used air tables for vibration isolation, which,

for the most part, performed adequately, Lin says. But use of the Sequel System

in more diverse locations, where low-frequency vibrations may be present to a

greater or lesser degree, necessitated a vibration isolator that was compact

enough to fit into our much smaller Sequel System and could effectively cancel

out these low-frequency vibrations.

Negative-stiffness vibration

isolation

Pacific Biosciences ultimately decided on negative-stiffness

isolation to address their needs. Developed by Minus K Technology,

negative-stiffness isolators use completely passive mechanical technology for

low-frequency vibration isolation without using motors, pumps, or chambers,

making them zero maintenance. Because of their very high vibration isolation

efficiencies, particularly in the low frequencies, negative-stiffness vibration

isolation systems enable vibration- sensitive instruments, such as the Sequel

System, to operate in severe low-vibration environments that wouldnt be

practical with top-performance air tables and other vibration-mitigation

technologies...

Full article...

|

|

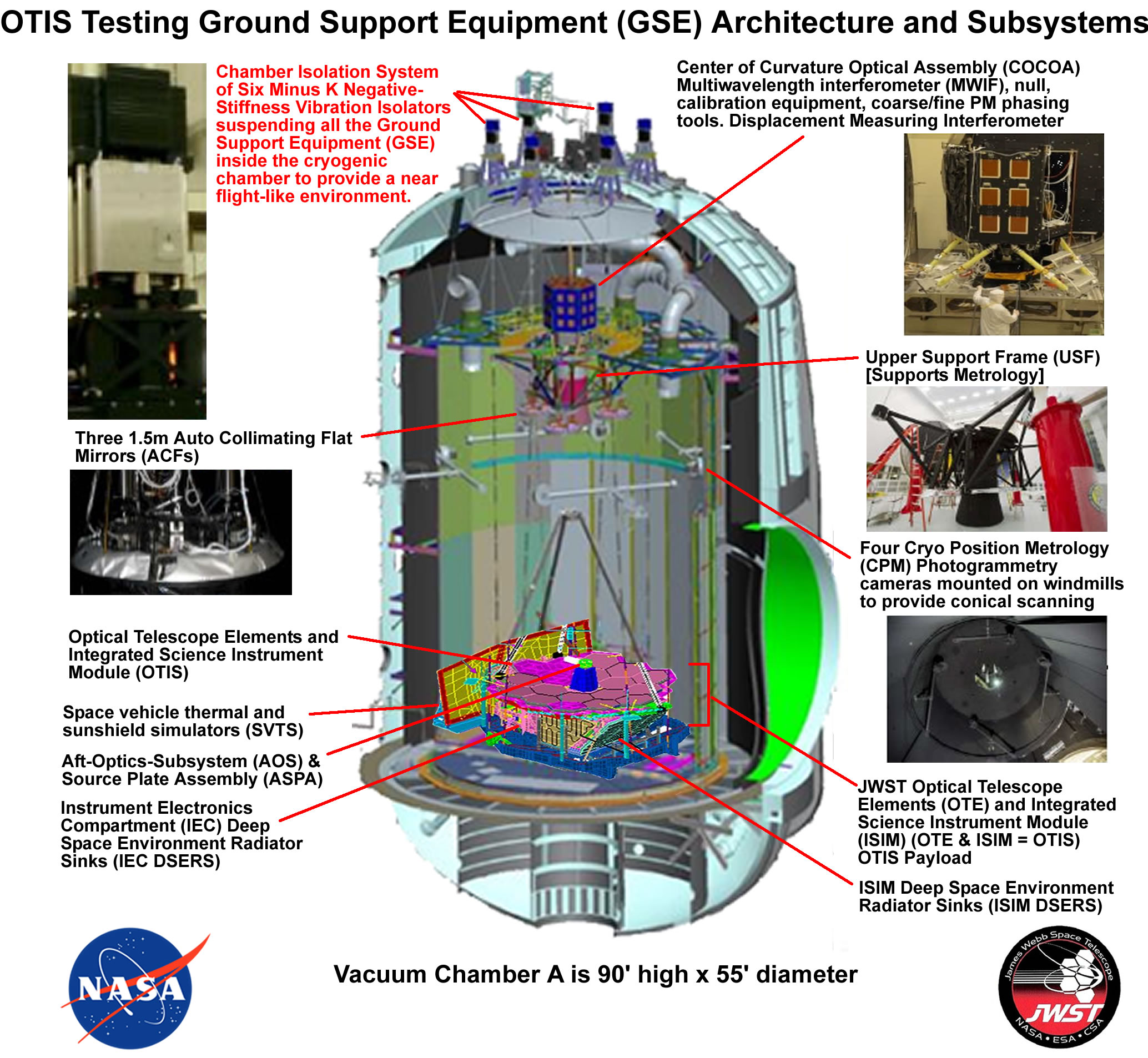

MInus K's Assist with the

Building of the JWST Telescope

|

|

All of the JWST systems-level cryogenic vacuum

tests were performed at the NASA Johnson Space Center’s (JSC) Chamber-A.

It is now the largest high-vacuum, cryogenic-optical test chamber in the

world, and made famous for testing the space capsules for NASA's Apollo

mission, with and without the mission crew. It is 55 feet (16.8 meters) in

diameter by 90 feet (27.4 meters) tall. The door weighs 40 tons and is opened

and closed hydraulically. The air in the chamber weighs 25 tons, when all the

air is removed the mass left inside will be the equivalent of half of a staple.

Diagram of the Cyrogenic Chamber in which the JWST

was tested for space.

For three years, NASA JSC engineers built and

remodeled the chambers interior for the temperature needed to test the James

Webb Space Telescope. Chamber A was retrofitted with the helium shroud, inboard

of the existing liquid-nitrogen shroud and is capable of dropping the chambers

temperature farther down than ever, which is 11 degrees above absolute zero (11

Kelvin, -439.9 Fahrenheit or -262.1 Celsius).

A key addition to Chamber

A was the addition of a set of six custom Minus K negative-stiffness

vibration isolators. The Minus K passive isolators do not require air and

offer better isolation than air and active isolation systems. A major factor in

the selection of the of the vibration isolators was that they not only isolate

vibration vertically, but also horizontally at less than 1 Hz.

JWST was

designed to work in space where the disturbances are highly controlled and only

come from the spacecraft, while on Earth with all the ground-based

disturbances, such as the pumps and motors, and even traffic driving by can

affect the testing. The Minus K vibration isolators provided dynamic isolation

from external vibration sources to create a near flight-like disturbance

environment.

The isolators utilize Minus K's patented Thermal

Responsive Element (TRE) compensator device, a passive mechanical device,

requiring no air or electricity just like the isolators. The TRE compensator

adjusted the isolators as the temperature changes throughout the testing at

JSC, keeping the JWST in the proper position.

The Critical Design Review

for Spacecraft-to-Optical Telescope Element vibration isolation system was

completed one month earlier than scheduled at the end of 2011. The six Minus K

negative-stiffness vibration isolators were installed on top of Johnson Space

Centers Thermal Vacuum Chamber A in March 2014.

JWST needed a support

structure inside the vacuum chamber to hold equipment for the testing.

Engineers installed a massive steel platform suspended from the six vibration

isolators via steel rods about 60 feet long (18.2 meters) each and about 1.5

inches (or 38.1 mm) in diameter, to hold the telescope and key pieces of test

equipment. The sophisticated optical telescope test equipment included an

interferometer, auto-collimating flat mirrors, and a system of photogrammetry

precision surveying cameras in precise relative alignment inside the chamber

while isolated from any sources of vibration, such as the flow of nitrogen and

helium inside the shroud plumbing and the rhythmic pulsing of vacuum

pumps.

Minus K's Involvement

continued...

-How much

farther can JWST see than the Hubble?

-Why was

it launched from near the equator?

-How cold

does the JWST get in space?

-How did

origami play into the trip?

-Why

24-karat gold on the mirrors?

Full article...

|

|

Our 29th

Anniversary is on 2/1/22

See the Milestones & Timeline

1993-2022

| Founded in

1993 |  |

|

|

Minus

K Technology Opens

| |

Minus

K Technology opens for business in

February 1993 |

|

Minus K's original SM-1 patented

Negative-Stiffness passive vibration isolator. This was the first commercialy

available vibration isolator offering 0.5 Hz natural frequencies for both

vertically and horizontally. This was accomplished without the use of air

compressors, computer componets or electricity.

The isolator could be used alone, or in conjunction with other units, and

could be engineered directly into a system. | |

Original

SM-1 Vibration Isolator

|

Our 29th

Anniversary is on 2/1/22

See the Milestones & Timeline

1993-2022

|

Within Saint Louis University’s (SLU)

Department of Physics, research has been ongoing in the development of novel

techniques for synthesis, characterization and measurement of low dimensional

(1D and 2D) systems. This is in hopes to better understand how size, geometry

or interfacing various materials and nanostructures influences the properties

of the resulting systems.

Nanolithography Research

Nanolithography in general terms is concerned with the study and

application of fabricating nanometer-scale structures, meaning patterns with at

least one lateral dimension between 1 and 100 nm. A prime focus is very

largescale integration (VLSI) and ultralarge-scale integration (ULSI)

technology of nanoelectromechanical (NEMS) systems, and the need for better

atomic-scale understanding of issues arising from the miniaturization of

silicon devices. Under the direction of Dr. Irma Kuljanishvili, who heads up

SLUs nanomaterials and nanofabrication research lab, the groups focus is on

This approach is similar to a technique known as dip pen

nanolithography.

In this technique, AFM tips or sharp needles can be

employed to transfer small, femtoliter volumes of molecular solutions, or other

liquid-based ink, to predefined locations on the surface of

samples.

Carbon nanotubes, grapheme and other atomically monolayered

materials are being considered as prime candidates for nanoscale science and

technology applications, due to their unique and superior combination of

electrical, thermal, optical and mechanical properties, says

Kuljanishvili.

SLU's Negative-Stiffness Vibration Isolation

System

Full article...

|

|

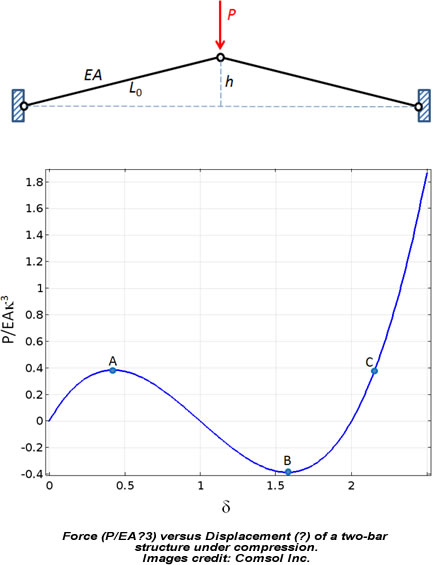

Notice that between points A and B, displacement is

increasing while force is decreasing. Thus, the structure’s stiffness is

negative in that region.

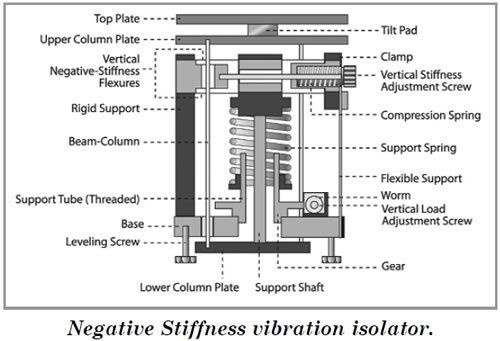

Negative-stiffness vibration isolators consist

of a horizontal isolator and a vertical isolator connected in series. To

counter motions that involve rotation (pitch and roll), a tilt motion pad can

also be connected in series with the horizontal and vertical isolators.

The horizontal isolator consists of two fixed-free vertical beams

(columns) supporting a weight. The weight imparts both eccentric (off-axis)

axial compressive load and a transverse bending load. This phenomenon is

referred to as the beam-column effect and causes the lateral bending stiffness

of the beams to decrease. In effect, the isolator is acting as a horizontal

spring with a negative-stiffness mechanism.

The horizontal isolator

is designed to take advantage of the beam-column effect, allowing it to act

like a negative-stiffness mechanism.

Vertical motion is addressed using two horizontal

flexures loaded in compression, which form a negative-stiffness mechanism. The

flexures are supported at their outer ends and connected to a stiff spring at

their inner ends. The stiffness of the isolator is determined by the design of

the flexures and by their compressive load.

Two flexures, fixed at their outer ends and

connected to a spring at their inner ends, form a negative-stiffness mechanism

that isolates equipment from vertical motion due to vibrations.

Full article...

|

|

Press Release:

New Ultra-Thin

CT-2 Low-Frequency

Vibration Isolation Platform Adapts

to Space Constraints in Critical Micro-

and Nano-Microscopy

(replaces the CT-1)

Full

release... |

|

|

|

|

|