|

|

Newsletter June 2021 | Menu of Newsletters

BioOptics Vibration

Isolation | A Tool for Brain Discovery

The ability to measure micron-level

neuronal activity patterns in the mammalian neocortex is enabling insight into

brain sensory and motor processing functions related to cardiac fibrillation

and epilepsy. Voltage-sensitive dye, optical recording techniques, and

vibration isolation are key to the work.

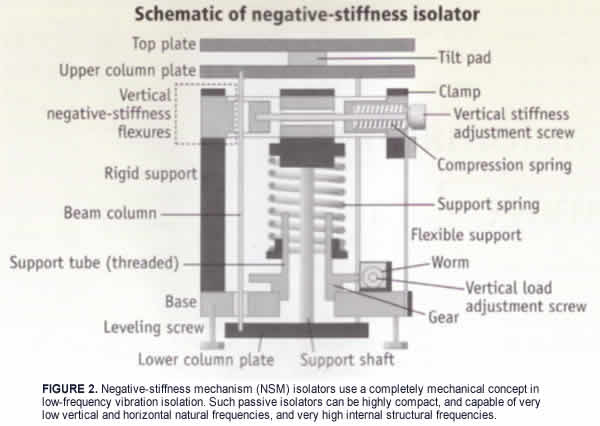

"At first, we used high-quality air

tables, but they were not adequate for isolating low frequency vibrations," but

then settled upon

negative-stiffness mechanism systems from

Minus K Technology. |

By Jim McMahon

(Legacy

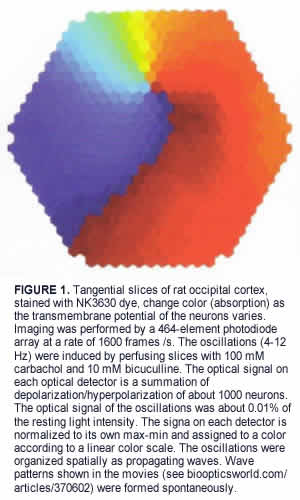

Article) Professor Jian-Young Wu has been conducting research on waves of

neuronal activity in the neocortex of the brain. Wu and his colleagues at the

Department of Physiology and Biophysics at Georgetown University Medical Center

visualize wave-like patterns in the brain cortex using optical imaging and

voltage-sensitive dyea method that depends on robust vibration isolation. Their

neuronal specimens are derived from slices of rat neocortex, the outer layer of

a mammal's brain, which is involved in higher functions such as sensory

perception and generation of motor commands and, in humans, language.

The neurons of the neocortex are arranged

in vertical structures called neocortical columns that measure about 0.5 mm in

diameter and 2 mm in depth. Each column typically responds to a sensory

stimulus representing a certain body part, or region of sound or

vision.

In the human neocortex, it is postulated that there are about a

half-million of these columns, each of which contains approximately 60,000

neurons.

The neocortex can be viewed as a huge web, consisting of

billions to trillions of neurons and hundred of trillions of interconnections.

While individual neurons are too simple to have intelligence, the collective

behavior of the billions of interneuronal interactions occurring each second

can be highly intelligent.

Full article... |

Negative-stiffness

Minus K BM-8 vibration isolator beneath the

Neubrescope.

By Jim McMahon

The latest

generation of fiber optic sensing systems employed to monitor well conditions

can augment operational performance in the oil & gas industry. Critical

data about the downhole well environment from distributed fiber optic sensing

(DFOS) systems improves engineers and scientists ability to arrive at decisions

that support operational optimization. This leads to well production

performance enhancement and safety at the well site, with the ultimate goal of

optimizing production from oil and gas wells. There is no other current method

to acquire the quality and level of detail about physical conditions in a

wellbore compared to fiber optics.

Distributed acoustic sensing (DAS) is

mainly used to listen to hydraulic fracturing related signals, fluid and gas

flow signals, or to sense seismic source response, such as in a vertical

seismic profile (VSP). DAS senses changes in small physical acoustic vibrations

along a glass fiber optic strand encased in a cable to measure vibrations.

There are thousands of detection points along the fiber in the subsurface fiber

optic cable.

DFOS is a technology that enables continuous, real-time

measurements along the entire length of a fiber optic cable at minimal spatial

intervals. Unlike conventional sensor systems that rely on discrete sensors

measuring at pre-determined points, distributed sensing does not rely upon

manufactured, discrete sensors, but uses the optical fiber itself as both

sensing device and two-way transmitter of the signal (light). Optical fiber is

the sensing element. without any additional transducers in the optical path.

Surface instruments called interrogator units (IU) send a series of laser light

pulses into the fiber and records the return of the naturally occurring

back-scattered light signal as a function of time. In doing this, the

distributed sensing system measures at all points along the fiber which are at

a pre-determined clock-time interval over periods of well operational

time

Because fiber optic cable can be installed in harsh environments

for long periods of time, the technology holds promise for environmental

monitoring of sensitive geologic operations. Many geofluid systems require

dynamic acoustic, temperature, strain and pressure monitoring at great

pressure, depth and temperature. Sensors that employ fiber optic cables serve

well for such deployments because they can withstand adverse environments.

Downhole application includes oil and gas wells (hydraulic fracture completion

operations, flow-back operations, long-term well monitoring, and well-integrity

monitoring), geothermal wells, deep industrial waste disposal wells and other

harsh environment applications.

Neubrescope set up on site near well

operations. Neubrescope set up on site near well

operations.

Full article... |

By Michael Fremer, Insider views on

everything vinyl

Let's begin by discussing what SAT's XD1 Record

Player System is not: It is not a Technics SP-10R in a sci-fiinspired

plinthalthough the XD1's engine does begin life as the SP-10R's basic drive

system, which is stripped down to a handful of essential components,

reimagined, reengineered, and rebuilt to much higher mechanical

standards..

Marc Gomez, SAT's designer, holds a master's degree in

mechanical engineering and materials science. Before dedicating himself to

creating the SAT tonearmby far the finest sounding and performing arm I've yet

encountered (as unanimously corroborated by Stereophile readers who bought this

very expensive product unheard as a result of my review)he was involved in a

variety of projects for, among others, the European Space Agency and various

European automobile manufacturers.

Even if it's not broken, why not

fix it?

The XD1 is a compact disc player, though not a player of compact

discs (footnote 1).

Its sculpted, satiny beauty goes beyond skin deep.

The XD1's metalwork, and that of the SAT tonearms, is machined at a Swedish

workshop that makes parts for Hasselblad cameras.

Gomez says that in

designing the XD1, he focused on four main areas: isolation from external

disturbances, speed stability, rigidity, and vacuum hold-down.

When Mr.

Gomez began conceptualizing his design a decade ago, it was immediately clear

to him, he says, that direct drive was the best way to spin a platter. His

reasons were these: A direct-drive motor's rotational speed is just 33.3, 45,

or 78rpm compared to several hundred rpm's required in the typical belt-drive

design, and with direct drive the spindle is not laterally loaded as it is in

belt-drive designs, so it receives only torque, not an off-center force. The

amount of torque available means the 'table is less likely to drag during

heavily modulated passages, something direct-drive advocates claim happens with

most belt designs.

Gomez says the drive-unit is no an off-the-shelf

motor designed for generic industrial applications. Rather, it is conceived and

built from the ground up to drive the XD1 (except for those few elements he

kept from the SP-10R motor, footnote 2). He says it's better balanced than the

motors typically used on belt-drive and idler turntables.

These claims

are hardly novel: If your old Technics SL-1200, which also uses a direct-drive

motor, could talk, it would make the same claims. Nor did Gomez address the

oft-cited disadvantages of direct-drive systems, which include motor "cogging"

(torque ripple), noise, and "hunting and pecking" as the quartz-locked system

readjusts to maintain speed consistency, a sort of analog "jitter" that

belt-drive advocates claim is sonically more pernicious than the slow, gradual

speed shifts a belt-drive table is more likely to experience.

Full article (with footnotes)...

|

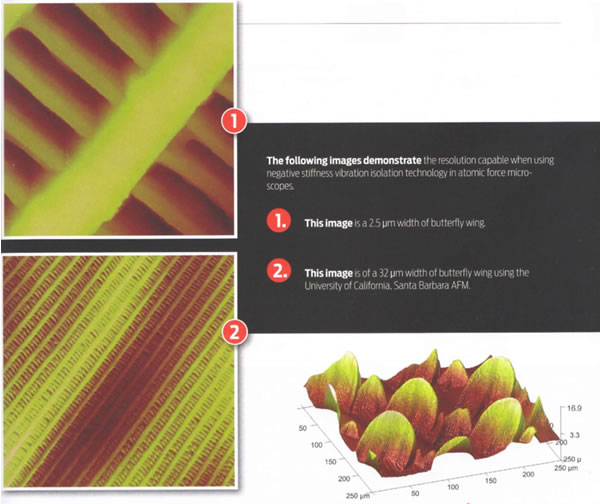

Here is an image of 250 µm width

of butterfly wing using University of California, Santa Barbara AFM with

negative-stiffness

vibration isolation.

(Lagacy 2013 article) With its

development in 1986, and subsequent commercial introduction in 1989, the

atomic force microscope

(AFM) is one of the foremost tools for imaging and measuring

materials and cells on the nanoscale. Revealing sample details at the atomic

level, with resolution on the order of fractions of a nanometer, the AFM is

instrumental for imaging an array of applications, such as defining surface

characterizations, lithography, datastorage, and manipulation of atoms and

nano-sized structures on a variety of surfaces.

The need for more

precise vibration isolation with AFM, though, is becoming critical as

resolutions continue to bridge from micro to nano.

AFM

systems are extremely susceptible to vibrations from the environment. When

measuring a very few angstroms or nanometers of displacement, an absolutely

stable surface must be established for the instrument. Any vibration coupled

into the mechanical structure of the instrument will cause vertical and

horizontal noise and bring about a reduction in the ability to measure with the

highest resolution.

The vertical axis is the most sensitive for AFMs,

but these microscopes are also quite sensitive to vibrations in the X and Y

axes.

The atomic force microscope uses a sharp tip (probe), with a

radius of curvature on the order of nanometers attached to the end of a tiny

cantilever used to scan across a sample surface to image its topography and

material properties. When the tip is brought into proximity of a sample

surface, forces between the tip and the surface lead to a deflection of the

cantilever This deflection is typically recorded using a laser beam that is

reflected from the top surface of the cantilever to a photosensitive detector.

The resultant position change of the cantilever allows characteristics such as

mechanical, electrostatic, magnetic, chemical and other forces to be precisely

measured by the AFM. These characteristics are displayed in a three-dimensional

surface profile of the sample (in the X, Y and Z axes)an advantage that the AFM

can provide compared to other microscopy techniques, such as the scanning

electron microscope (SEM) which delivers a two-dimensional image of a sample

(in the X and Y axes).

Minus K BM-1

Isolator.

Full article...

|

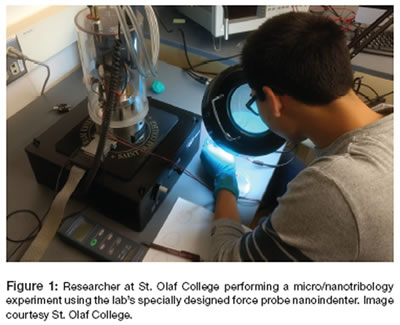

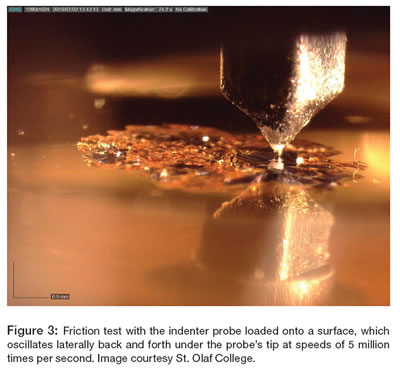

Abstract: Researchers in the Physics

Department of St. Olaf College are using a uniquely designed, integrated

nanoindenter-quartz microbalance apparatus to bridge the gap between the

fundamental science of friction and the engineering of practical

micromechanical systems. This level of micro-research requires extreme

stability for the microbalance instrumentation. Since 2001, the lab has used

negative-stiffness vibration isolation to achieve a high level of isolation in

multiple directions, custom tailoring resonant frequencies to 0.5 Hz vertically

and horizontally.

Introduction: Scientists do not fully

understand what causes friction and wear between two surfaces at the molecular

level. When designing a micromechanical system, the fundamental machine parts

of gears, hinges, pistons, gimbals, and suspended beams that flex are included.

Basic motions that are the essence of mechanics rely on these materials having

durability and low or controllable friction. Mastering these forces that occur

on small-scale surfaces of micromachines is a considerable challenge. When the

mechanical parts are very small, their properties are dominated by minute

surface forces that macroscopic machines are not sensitive enough to detect.

This raises entirely new questions about how to maintain minute components and

to keep them moving and protected from wear or breakage.

Silicon

Uniformity:

Engineers have relied on extremely thin lubricant films to

reduce friction and to keep parts moving inside tiny silicon-constructed

microelectromechanical systems (MEMS). But these films have not been

sufficiently effective in micromachines, which rely on relatively fast-moving

parts that are in contact with each other, such as gears, gimbals, and pistons.

Since the early 1980s, with the introduction of the first micromechanical

machines, the vision has been to batch-fabricate these devices as silicon chips

to link with circuitry that can be connected wirelessly. However, these small

silicon machines often disintegrate after just a few hours of operation. This

technology has, for some time, been struggling to make it to the marketplace.

Decades of research in both academia and business has been undertaken to

understand friction and wear well enough at these micro- and nano-scales to

effectively lubricate and provide wear protection.

New Research

Methodology:

Professor Brian Borovsky, Associate Professor in the

Physics Department at St. Olaf College in Northfield, MN, has been researching

micro/nanotribology for over two decades [14]. He has pioneered friction

research as applied to very tiny micromechanical machines, having developed

state-of-the-art instrumentation and a process that tests frictional properties

of surfaces coated with ultrathin lubricants. His is one of the few labs that

can measure friction of micromachine surfaces sliding past each other at very

high speeds that approach 1m/s.

While equipped with scanning electron

(SEM) and atomic force microscopy (AFM) for analysis of surfaces, the labs

focus instrumentation is a specially designed force probe nanoindenter in

conjunction with a quartz microbalance...

Full article...

|

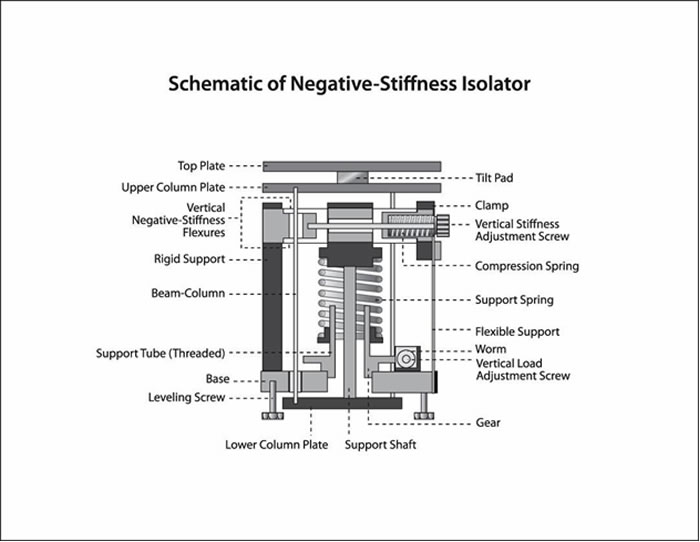

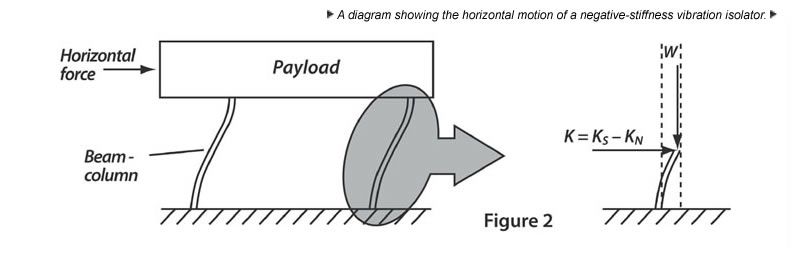

Commercial Micro Manufacturing -

Dec.2020

The need for nano- precision has became

increasingly important in many fields of research and manufacturing, inducing

microelectromcs fabrication, laser/optical system applications and biological

research. This has meant that so too has the need for vibration Isolation

technology that better facilitates the operation of sensitive Instrumentation

such as

atomic force microscopes, scanning tunneling

microscopes,

laser interferometers and optical

profilers.

Once the mainstay for stabilizing academia's

and Industry's most critical microenginering instrumentation, pneumatic (gas or

air pressurized) vibration Isolation tables are today proving unsatisfactory in

isolating disruptive

low-frequency vibrations. There is a growing trend

for locating sensitive instrumentation in building to locations that are

subject to extremely high levels of vibration and this is a significant

stumbling block for pneumatic vibration isolation tables, meaning alternative

vibration isolation solutions are required.

Vibration

sources

Nano-level instrumentation is sensitive to extremely small

payload vibrations that can be caused by a multitude of factors. Every

structure (building) transmits vibrations from Internal and external sources In

a building, heating and ventilation systems, fans, pumps and elevators are Just

some of the mechanical devices that create vibrations. Outside a building,

adjacent road traffic, nearby construction, aircraft and even wand and other

weather conditions all create vibrations How strongly the instrumentation is

influenced depends on where it is in the building and how far away it is from

the vibration sources.

Isolation for vibration

critical applications

Over the past 25 years, two technologies have

gained prominence for their ability to Isolate vibrations Influencing

nano-level Instrumentation, namely active vibration isolation (also known as

electronic-force cancellation) and negative-stiffness vibration isolation {also

known as passive vibration isolation).

Both active and

negative-stiffness vibration isolation are uniquely equipped for applications

where structures smaller than a micrometre need to be produced or measured.

These technologies provide functionality that is typically not achievable with

pneumatic vibration isolation tables.

Full article: Comparing systems...

|

|

Press Release:

New Ultra-Thin

CT-2 Low-Frequency Vibration

Isolation Platform Adapts

to Space Constraints in Critical Micro- and

Nano-Microscopy

(replaces the CT-1)

Full

release... |

|

You might have thought, maybe for only a

few moments, that your

audio system was

sounding especially good. With that feeling, you would have rated the sound a

top score of "10". Then those magical moments ended and your system returned to

it's normal - but still good - performance level. Well, folks, the Minus K

CT-2 Isolation

Platform could raise your system score to an "11" and keep it there! Highly

recommended for systems that are already high performance and where you want to

coax the maximum performance from your audio investment....

Dr. David L.

Platus is President and Founder and is the principal inventor of the

technology. He earned a B.S. and a Ph.D. in Engineering from UCLA, and a

diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to

founding Minus K® Technology he worked in the nuclear, aerospace and

defence industries conducting and directing analysis and design projects in

structural-mechanical systems. He became an independent consultant in 1988. Dr.

Platus holds over 20 patents related to shock and vibration

isolation.

Ultra-Thin 2.7" High

CT-2 Product

Attributes:

- Isolation performance is typically 10 to 100 times

better than air systems

- No air or electric power is

required

- Nothing to wear out

- No

maintenance

A complete description of the

patented

Negative-stiffness design can be found on the

Technology page of the manufacturers Web site. The Minus K platform is

completely silent and requires no pumps or power. The

CT-2 model platforms

are available for different weight ranges of payload, or supported weight. The

40CT-2 model, while not specifically listed on the Web page, was perfect for

the Clearaudio Ovation

turntable used for

this review. The platform dimensions are 18" W x 20" D x 2.7" H, with a weight

of about 30 pounds. Different models, for different payloads, range in price

from $4,650 to about $5,250. In my system, the platform was installed 20" W x

18" D, which placed the adjustment crank on the 18" left side.

The

horizontal frequency of ~1.5 Hz is achieved at or near the upper limits of the

payload range. The vertical frequency is tunable to 0.5 Hz throughout the

payload range. What this means is that any very low frequency vibrations that

are not blocked or absorbed by the Minus K platform are several orders of

magnitude below what your phono cartridge, or even the best subwoofers, can

process.

Full article...

|

3D Surface Analysis Vibration

Isolation

High-precision, nanometer-level 3D surface

measurement systems can be negatively affected by low-frequency

vibration—distorting imaging and producing inaccurate measurement

readings. |

Manufacturers need to control processes to

produce a consistent, reliable product. Where precision surface engineering is

required, surface measurement may be a key part of maintaining control of the

process, by checking output to see that the process is not outside of

specification.

3D non-contact surface analysis is widely used in the

industry for the measurement of small displacements and surface irregularities.

It delivers the ultimate in high accuracy and repeatable and traceable

measurement. When built into microscopy equipment, employing 3D laser scanning

or structured light, these systems report the surface condition of a product

with more accuracy than any other methodproviding nanometer-level profile

measurements of height, width, angle, radius, volume, and roughness. Such

precision measurement systems allow users to improve product quality and

reliability, and increase manufacturing consistency and production

yields.

Low-Frequency Vibration

When measuring at such high

levels of precision, any instrument can be negatively affected by low-frequency

vibrations generated within a manufacturing facility. These can distort

measurements and impact imaging and measurement data

One company that

has great familiarity with the manufacturing environment and 3D surface

measurements is Keyence Corporation--a leading supplier of sensors, measuring

systems, laser markers, microscopes, and machine vision systems

worldwide.

We have many customers with high-precision 3D measurement

systems operating in high-vibration environments, performing microscopy

evaluation at 30,000 times magnification, looking at nanometer-level surface

features, said Evan Eltinge, Senior Sales Engineer Surface Analysis Team, with

Keyence Corporation of America. At that level of detail, and in that

environment, if measures are taken to reduce vibration it improves the quality

of the data.

Without proper isolation surface measurements occurring at

3,000 to 5,000 times magnification, the vibration could contribute to image

blurring and loss of image quality, continued Eltinge.

Vibration can be

caused by a multitude of factors within a plant; every structure is

transmitting noise. Within the building itself, production machinery, forklift

trucks, the heating and ventilation system, fans, pumps, compressors, and

elevators are just some of the mechanical devices and equipment that create

low-frequency vibration. Depending on how far away the surface measurement

instrumentation is from these vibration sources, and where inside the structure

the instrumentation is locatedwhether on the production floor or in a loftwill

determine how strongly the instrumentation will be influenced.

External

to the building, the equipment can be influenced by vibrations from truck

movement, road traffic, nearby construction, loud noise from aircraft, and even

wind and other weather conditions that can cause movement of the

structure.

Vibration Isolation Options for 3D Surface

Analysis...

Full article...

|

|

|

|

|

|

|